CEB Press: Difference between revisions

| Line 40: | Line 40: | ||

*Weight - 1700 lb | *Weight - 1700 lb | ||

*Moving: brick press is moved with forks. Footprint (with legs in the inner position) allows machine to be placed in the bed of a 3/4 ton pickup. It has adjustable legs for uneven terrain. Machine can be moved around on a trailer (not included) | *Moving: brick press is moved with forks. Footprint (with legs in the inner position) allows machine to be placed in the bed of a 3/4 ton pickup. It has adjustable legs for uneven terrain. Machine can be moved around on a trailer (not included) | ||

*Material cost: $4500-$6500 depending on sourcing; manual machine (without hydraulic solenoid, machine costs $1000 less in materials | *Material cost: $4500-$6500 depending on sourcing; manual machine (without hydraulic solenoid, machine costs $1000 less in materials. Production cost for a full kit: US$5000 above the bill of materials cost, paid by the buyer. Production currently occurs in [[Extreme Manufacturing]] Workshops - where the buyer is invited to the build so they understand how the machine is built - and is part of the buyer's Lifetime DIY Warranty. This warranty means that the user can maintain the machine for decades because they know how the machine is built, how it works, and how to source parts for the machine from local and online sources. This means that this is not a consumer machine, but a prosumer machine. | ||

*3'x6' grate for tractor loading. Includes soil deflectors | *3'x6' grate for tractor loading. Includes soil deflectors | ||

*Includes hopper shaker to help soil move down the hopper | *Includes hopper shaker to help soil move down the hopper. However, the shaker is not needed if soil quality is good. | ||

*Known bugs: machine has currently been tested in multiple day production runs and is stable at 6 bricks per minute. When solenoid valve | *Known bugs: machine has currently been tested in multiple day production runs and is stable at 6 bricks per minute. | ||

:*When solenoid valve runs with 2 Power Cubes at 28 gpm fluid flow, different control code needs to be used. The updated control code is designed for parallel operation, which does not work well with a series valve. | |||

:*Issue can be resolved also by using the same code, and a parallel solenoid valve instead of the series solenoid valve that is currently being used | |||

:*This bug was not seen when a larger diesel engine was used to power the brick press in 2010 at 30 gpm fluid flow, because the simpler control code at that time was written for series operation. | |||

:*Control code optimization needs to happen to optimize power usage | |||

:*Log splitter hydraulic pumps can be used to allow for the use of a smaller engine. This has not been done yet. | |||

=Versions= | =Versions= | ||

Revision as of 02:34, 22 June 2016

Link to CEB Press Build June 2015

The CEB Story 2012. from Open Source Ecology on Vimeo.

| CEB Press | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

The Liberator is OSE's automatic, high throughput Compressed Earth Brick Press. It is named The Liberator because it is intended to free people from the single highest cost of living - housing. See Cost of Living and GVCS Naming Convention.

The CEB is at product release status and is being actively manufactured at Factor e Farm. The presses was used heavily as a part of the Factor e Farm Infrastructure Buildout 2011. See latest press release on the MicroHouse 4 built in 2014 - [1]

The bill of materials cost of the machine is $3000-5500, depending on the version and build process. The machine versions include:

- manual hydraulic controls

- digitally cut parts or stock steel sections

- small or large hopper

- with or without hopper shaker

- automatic controller at 5 bricks per minute

- automatic controller at 10 bricks per minute

We are currently selling the full machine for $11k (specifications below). We are currently accepting requests to be put on a product order wait list, and we will set up production capacity to fill regular orders in late 2016. - Updated Sep. 2015.

Specifications

- Version 6 is our current model; exhaustive documentation release comming 4/30/15

- Open source hardware, controller, and software (CC-BY-SA, GPL)

- Controller includes automatic pressing and manual mode

- Does NOT come with a power source - it is powered by a hydraulic power source, such as by our Power Cube or a tractor hydraulic take-off.

- Full size bricks are 4"x6"x12", plain flat-faced bricks

- Brick height is adjustable from 1"-4"

- Brick dimensional variations: +/- 1/16". Soil uniformity will determine height uniformity of brick.

- 6 full-sized bricks per minute at 14 gallon per minute hydraulic flow. Brick pressing rate will increase with a higher hydraulic flow, up to the maximum rated flow of the hydraulic solenoid. At a flow >14 gpm, the secondary cylinder and shaker motor are throttled down to reduce their speed. Hydraulic solenoid valve is rated for a maximum of 30 gpm fluid flow at 3000PSI

- Fuel consumption with Power Cube running at 14 gpm fluid flow - about 1 gallon per hour

- System hydraulic pressure - 2300 psi

- Comes with hydraulic quick couplers ready to be connected to a power source

- Weight - 1700 lb

- Moving: brick press is moved with forks. Footprint (with legs in the inner position) allows machine to be placed in the bed of a 3/4 ton pickup. It has adjustable legs for uneven terrain. Machine can be moved around on a trailer (not included)

- Material cost: $4500-$6500 depending on sourcing; manual machine (without hydraulic solenoid, machine costs $1000 less in materials. Production cost for a full kit: US$5000 above the bill of materials cost, paid by the buyer. Production currently occurs in Extreme Manufacturing Workshops - where the buyer is invited to the build so they understand how the machine is built - and is part of the buyer's Lifetime DIY Warranty. This warranty means that the user can maintain the machine for decades because they know how the machine is built, how it works, and how to source parts for the machine from local and online sources. This means that this is not a consumer machine, but a prosumer machine.

- 3'x6' grate for tractor loading. Includes soil deflectors

- Includes hopper shaker to help soil move down the hopper. However, the shaker is not needed if soil quality is good.

- Known bugs: machine has currently been tested in multiple day production runs and is stable at 6 bricks per minute.

- When solenoid valve runs with 2 Power Cubes at 28 gpm fluid flow, different control code needs to be used. The updated control code is designed for parallel operation, which does not work well with a series valve.

- Issue can be resolved also by using the same code, and a parallel solenoid valve instead of the series solenoid valve that is currently being used

- This bug was not seen when a larger diesel engine was used to power the brick press in 2010 at 30 gpm fluid flow, because the simpler control code at that time was written for series operation.

- Control code optimization needs to happen to optimize power usage

- Log splitter hydraulic pumps can be used to allow for the use of a smaller engine. This has not been done yet.

Versions

- CEB Press 6

- CEB Press 5

- CEB Press 4

- CEB Press 3

- CEB Press 2

- Prototype 1 Completed blog post

Details

The CEB Press takes earth/dirt/soil and compresses it tightly to make solid blocks useful for building. Compressed earth blocks have many advantages as a building material: by making the building materials from the readily available dirt on the building site, they eliminate the need to transport bricks from elsewhere, reducing financial cost and environmental impact. Compressed earth blocks are very strong and insulate well against both heat and sound, making for very energy-efficient building (especially combined with the energy savings from not needing to transport them from offsite). Best of all, the material they use is already on-site and does not need to be purchased -- quite literally, dirt-cheap! See the wiki page on Compressed Earth Blocks and the CEB category for more details on building using CEBs.

The Liberator has been fully designed and tested by the Open Source Ecology team. Because the Liberator is an open source technology, you can freely download instructions to build your own from materials you can obtain yourself, or contact opensourceecology[at]gmail[dot]com to buy a kit or a finished machine.

Building a machine yourself might seem intimidating, but every step of the process is fully documented and the OSE community is available on our discussion forums if you need help, advice, or a little hand-holding.

Using the CEB Press, two people can build a 6 foot high (1.83m) round wall, 20 feet (6.1m) in diameter, 1 foot (30cm) thick, in one 8 hour day, though construction time will vary somewhat depending on preparation time, what equipment is available (tractor to prepare the ground and move the blocks where they need to go), the quality of the soil, and other factors. The bigger the block size, the faster a wall can be erected, but at the cost of heavier blocks that are more of a strain to work with. Blocks from The Liberator average 25 pounds (11.3kg).

See CEB Design for more information.

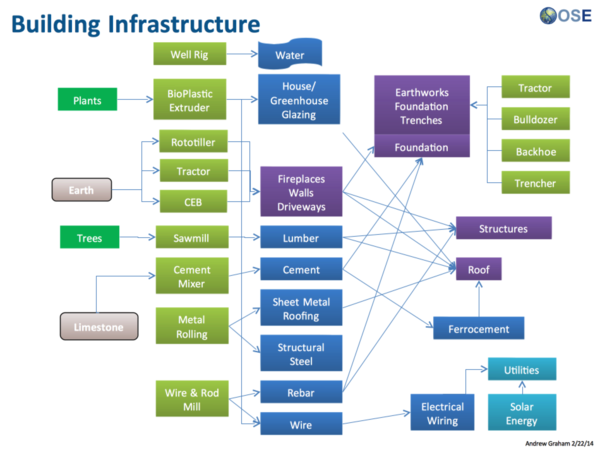

Product Ecology

From

Uses

Creates

Enables

See Also

- Soil Testing

- more Soil Testing

- CEB Design

- Compressed Earth Blocks

- Cinva Ram

- CEB_FAQ

- CEB Press/Rollers

- CEB Press/ModularRollers

- Hablab

- Metric CEB Press

- Field Testing 2011

- CEB Press/Videos