D3D Universal: Difference between revisions

| Line 292: | Line 292: | ||

=Build, Production Manuals= | =Build, Production Manuals= | ||

*[[D3D Universal Build Manual]] | *[[D3D Universal Build Manual]] | ||

=D3D Universal Production Manual= | |||

*[[D3D Universal Production Manual]] | *[[D3D Universal Production Manual]] | ||

Revision as of 19:53, 28 February 2020

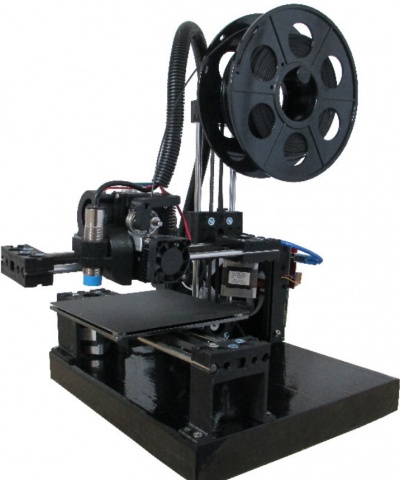

We are now producing kits and finished machines - see https://www.opensourceecology.org/d3d-universal-2/

![]() Hint: Our next build workshop is March 14 - 17 - see https://www.opensourceecology.org/steam-camp-march-2020/

Hint: Our next build workshop is March 14 - 17 - see https://www.opensourceecology.org/steam-camp-march-2020/

Product

CAD

3D Printer

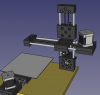

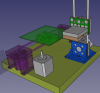

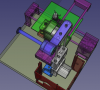

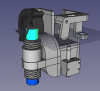

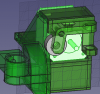

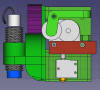

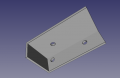

D3D Universal Rework - [1]. Newer - File:D3D Universal Assy.fcstd. Note: sensor holder is old fine in assemly; Extruder separate file for sensor holder is correct.

D3D Universal - scaled to 12" print bed - FreeCAD - File:D3du12inchscaled.fcstd

D3D Universal Rework X Axis - File:D3D Universal X Axis.fcstd

D3D Universal Rework Y Axis - File:D3D Universal Y Axis.fcstd

D3D Universal Print Bed - File:D3D Universal Print Bed.fcstd

D3D Universal Rework Z Axis - File:D3D Universal Z Axis.fcstd

D3D Universal Rework Base - File:D3D Universal Base.fcstd

Spool holder assembly- File:Spoolholdersassy.fcstd

Spool- File:Filamentspool.fcstd

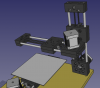

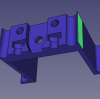

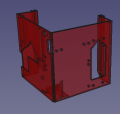

D3D Universal Rework Controller - File:D3D Universal Controller.fcstd

D3D Universal Rework Spool Holder - FreeCAD - File:D3D Universal Spool Holder.fcstd. STL - File:D3D Universal Spool Holder.stl

Spool holder rod . FreeCAD - File:Spoolholderrod.fcstd. STL - File:Spoolholderrod.stl

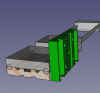

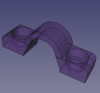

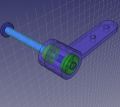

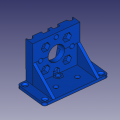

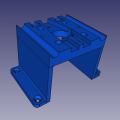

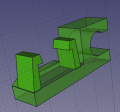

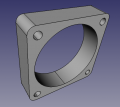

[10] Motor Side of Axis - 221k - FreeCAD -File:Universal axis motor side.fcstd. STL - File:Universal axis motor side.stl

[10] Motor Side of Axis - 221k - FreeCAD -File:Universal axis motor side.fcstd. STL - File:Universal axis motor side.stl

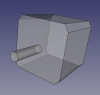

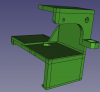

Universal axis carriage: File:Universal axis carriage side.fcstd. STL - File:Universal axis carriage side.stl

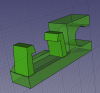

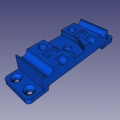

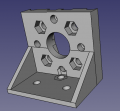

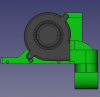

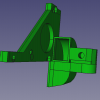

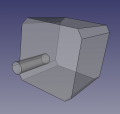

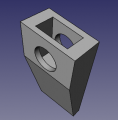

[10] Short Idler Side - 75k - FreeCAD - File:Universal Axis Idler Side short version.fcstd. STL - File:Universal Axis Idler Side short version.stl.

[10] Short Idler Side - 75k - FreeCAD - File:Universal Axis Idler Side short version.fcstd. STL - File:Universal Axis Idler Side short version.stl.

Carriage to side motor piece- FreeCAD - File:Carriagetosidemotor.fcstd. STL - File:Carriagetosidemotor.stl.

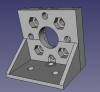

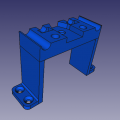

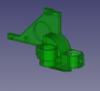

D3DS motor piece with bracket for x and z-axis

FreeCAD file -File:D3DS motor bracket.fcstd

STL file -File:D3DS motor bracket.stlD3DS idler side piece for Y-axis

FreeCAD file -File:D3DS idler screwdown.fcstd

STL file -File:D3DS idler screwdown.stlD3DS elevated idler side piece for Y-axis

FreeCAD file -File:D3DS idler high screwdown.fcstd

STL file -File:D3DS idler high screwdown.stlD3DS motor side piece for Y-axis

FreeCAD file -File:D3DS motor side screwdown.fcstd

STL file -File:D3DS motor side screwdown.stlD3DS elevated motor side piece for Y-axis

FreeCAD file -File:D3DS motor side high screwdown.fcstd

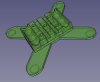

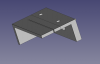

STL file -File:D3DS motor side high screwdown.stlMount of Z motor to base plate. File:D3DS motor bracket x axis.fcstd. STL - File:D3DS motor bracket x axis.stl3D Printed Bed Holder File:Newbed.fcstd. STL - File:Newbed.stl

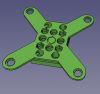

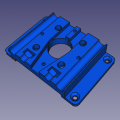

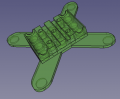

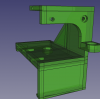

[10] Belt Holding Peg - FreeCAD original size - File:Peg 8mm rods.fcstd. STL at 85% size, works well - File:Peg 8mm rods.stl

[10] Belt Holding Peg - FreeCAD original size - File:Peg 8mm rods.fcstd. STL at 85% size, works well - File:Peg 8mm rods.stl

'Cable clip for end of axis nut catch. - FreeCAD - File:Cableclip2.fcstd. STL - File:Cableclip2.stl

Endstop holder. - File:Endstopholder2.fcstd. File:Endstopholder2.stl. See Open Source Endstop Holder

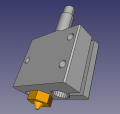

Printer Extruder

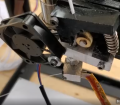

![]() Hint: Note the small extruder gear shown is MK8- we are using an MK7. Note: Supervolcano nozzle has heat transfer issues, so we are using a 3 mm E3D v6 heat break with success (6mm threads on both sides - note that E3D v6 has 6 mm on the nozzle side, 7 mm on the cold side. Can also test Titan Aero v6 1.75 mm - which appears to have 6 mm thread on both sides. 3mm titan aero is definitely 6 mm thread on each side: see E3D_Titan_Aero_Extruder#CAD

Hint: Note the small extruder gear shown is MK8- we are using an MK7. Note: Supervolcano nozzle has heat transfer issues, so we are using a 3 mm E3D v6 heat break with success (6mm threads on both sides - note that E3D v6 has 6 mm on the nozzle side, 7 mm on the cold side. Can also test Titan Aero v6 1.75 mm - which appears to have 6 mm thread on both sides. 3mm titan aero is definitely 6 mm thread on each side: see E3D_Titan_Aero_Extruder#CAD

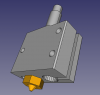

Notes: Still missing from final assembly by MJ: fan, heat sink heat exchanger, MK7 gear, spring. In final CAD of extruder assy, heat break does not stick out of the heat sink. In reality, it sticks out about 3 mm. Where is the discrepancy if the heat break is 25 mm long?

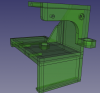

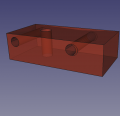

Simple Extruder WIP. Github - [2]. Gitlab - [https://gitlab.com/marcin_ose/d3d-universal.

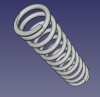

Extruder Spring for Simple Extruder. Buy + spec - [3]. FreeCAD file - File:Extruderspring.fcstd

Extruder assembly - Gitlab - [4]. FreeCAD - File:Simpleextruderassy.fcstd

Main extruder part. - Gitlab - [5]. FreeCAD - File:Mainextruderpart.fcstd. STL - File:Extruder main.stl

Extruder Active Cooling and Sensor Mount File:ExtruderActiveCoolingAndSensor.FCStd. STL - sensor holder - File:SensholderSimple.stl

Extruder Active Cooling with Sensor Mount + Plotter Mount File:ExtrCoolSensPlt.fcstd. STL - Cooling/Sensor/Plotter Mount - File:ExtrCoolSensPlt.stl

Spring tensioner -File:SpringTensioner.FCStd. STL - File:Tensioner.stl

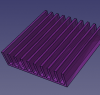

Jig to cut the heat sink -File:HeaterSinkJig.FCStd

heat sink -File:HeatSink.FCStd. Technical drawing - File:Heatsinktechdraw.FCSTD

Spiral linear bearing - parametric, but parameters set up for D3D -File:SpiralLinearBearing.zip

Volcano heater block. File:Volcanoheaterblock.fcstd.

File:5015blower.fcstd 5015 Blower - positionally correct for D3D Universal.

8 mm sensor. Download - File:8mmsensor.fcstd

608 skateboard 8x22x7 mm Bearing. Download - File:608Bearing.FCStd

40x10mm fan File:40x10fan.fcstd

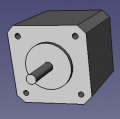

Stepper MotorFile:Steppermotor.fcstd

Stepper Motor from FaceplateFile:Nema17face.fcstd

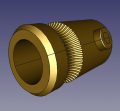

Super Volcano NozzleFile:SuperVolcanoNozzle.fcstdDrive GearFile:Drivegear.fcstd

3 mm heat break.File:3heatbreak.fcstd. Re-Source - [6]

4040 heatsink.File:Heatsink.fcstd

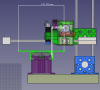

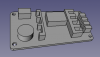

Control Panel

See more at 3D Printer Control Panel

Control Panel - FreeCAD -File:Controlpanel v1904.fcstd. Bent panel STL - File:Bentpanel v1904.stl

D3D v19.04 Power Supply - FreeCAD -File:Powersupply v1904.fcstd

RAMPS 1.4 - FreeCAD -File:RAMPS14 v1904.fcstd. Full detailed file - 4MB - [7]

Stepper driver - FreeCAD -File:Stepperdriver v1904.fcstd. File for detailed LCD controller and endstop can be found at [8]

Solid state relay - FreeCAD -File:Ssr v1904.fcstd. Source: [9]. See Fotek SSR. Dimensions verified with Amazon source.

Reprap Discount Smart Controller - FreeCAD -File:Smartcontroller v1904.fcstd. Source: [10].

Ground Fault Connection Interrupt (GFCI) outlet - FreeCAD -File:Gfci v1904.fcstd. CAD source at McMaster Carr: [11]. May not represent actual GFCI.

Wire box cover. - FreeCAD -File:Wireboxcover v1904.fcstd.

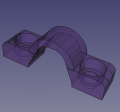

Power cord wire clamp - FreeCAD -File:Heatbed wirelock.fcstd.

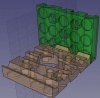

Inner part of D3D Electric Plug - FreeCAD File:D3DPlugInner.fcstd. STL - File:D3DPlugInner.stl

Outer cover of D3D Electric Plug - FreeCAD File:D3DPlugCover.fcstd. STL file is scaled to 105% already - File:D3DPlugCover.stl

Plotter

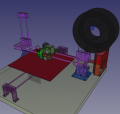

![]() Hint: Amazing, works out of box. Improvements: raise tip next to carriage. Double-sided attachment. Probe on right, not left, to optimize print area

Hint: Amazing, works out of box. Improvements: raise tip next to carriage. Double-sided attachment. Probe on right, not left, to optimize print area

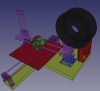

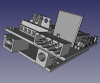

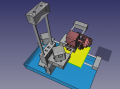

D3D Universal with 3D printer motor functioning as a CNC mill. - FreeCAD -[12] or Michel's repo.

D3D Simple Working Copy by Marcin - FreeCAD -File:D3Dsimple.fcstd

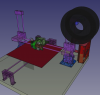

D3D Universal with plotter attachment. - See D3D Universal Plotter by Ferdi Meier. Gitlab - [13]

Plotter Pen Attachment. - File:Plotterpen.fcstd. Start from Ferdi Log, adaptation by Marcin Log. STL printed - File:Plotterpen.stl.

Simple extruder for 1.75 mm filament. - By London International Academy team. From Simple Extruder.

Pen holder clamp for plotter - includes sensor holder - File:Penholderclamp.fcstd. STL - File:Penholderclamp.stl

Mill

Simple spindle - By John Stager team. See Simple Spindle.

Arduino Uno for motor power supply. See Emmanuel Log.

Technical Drawing Library

Useful technical drawings for fabricating parts:

- File:Heatsinktechdraw.FCSTD - heat sink dimensional drawing

Diagram

BOM

Working Doc

Includes Review and Data Collection

| Description | Link to Work Product | % | |

|---|---|---|---|

| DESIGN | |||

| 1 | Requirements + Value Proposition | [[{{{0}}} Requirements + Value Proposition]] | {{{1}}} |

| 2 | Industry_Standards | [[{{{0}}} Industry Standards]] | 50 |

| 3 | Conceptual Design | [[{{{0}}} Conceptual Design]] | {{{3}}} |

| 4 | Module Breakdown | [[{{{0}}} Module Breakdown]] | {{{4}}} |

| 5 | 3D CAD | [[{{{0}}} 3D CAD]] | {{{5}}} |

| 6 | Calculations | [[{{{0}}} Calculations]] | {{{6}}} |

| 7 | Electronics Design | [[{{{0}}} Electronics Design]] | {{{7}}} |

| 8 | Wiring and Plumbing | [[{{{0}}} Wiring and Plumbing]] | {{{8}}} |

| 9 | Software | [[{{{0}}} Software]] | {{{9}}} |

| BILL OF MATERIALS | |||

| 10 | BOM | [[{{{0}}} BOM]] | 50 |

| 11 | vBOM | [[{{{0}}} vBOM]] | {{{11}}} |

| 12 | CAM Files | [[{{{0}}} CAM Files]] | {{{12}}} |

| 13 | Cut List | [[{{{0}}} Cut List]] | {{{13}}} |

| BUILD | |||

| 14 | Build Instructions | [[{{{0}}} Build Instructions]] | 20 |

| 15 | Fabrication Drawings | [[{{{0}}} Fabrication Drawings]] | {{{15}}} |

| 16 | Exploded Part Diagram | [[{{{0}}} Exploded Part Diagram]] | {{{16}}} |

| 17 | Production Engineering | [[{{{0}}} Production Engineering]] | {{{17}}} |

| DATA COLLECTION | |||

| 18 | Build Pictures and Video | [[{{{0}}} Build Pictures and Video]] | {{{18}}} |

| 19 | Data Collection | [[{{{0}}} Data Collection]] | {{{19}}} |

| 20 | Future Work | [[{{{0}}} Future Work]] | {{{20}}} |

Build

Cut List

- [6] 8 mm rods, 12" each

- [1] 8 mm rod, 3D printed,

- [1] 2x12 lumber, 12.5" long

- [3] belts, 26" long

D3D Universal Axis

Platform on stilts so extruder reaches bed:

Nozzle does not reach bed:

Extruder Build

Plotter Build

Design Concepts

Plotter

embedded my website on wiki https://feadi.github.io/OSE/.

Played with gtlf-viewer

Wiring

Software

- Printer - Marlin, Lulzbot Cura, OSE Linux, FeF Microfactory printer profiles

Plotter File Generation

- Plotter - Using Inkscape to Generate Gcode

Code

Firmware

- Marlin - File:Marlin Universal.zip

Production Engineering

D3D Universal Production Engineering

Product

See D3D Universal Product Page.

Build, Production Manuals

D3D Universal Production Manual

Troubleshooting

- D3D Universal Troubleshooting Guide - add videos

Clog troubleshooting 1st step in checklist [16]

![D3D Universal Rework - [1]. Newer - File:D3D Universal Assy.fcstd. Note: sensor holder is old fine in assemly; Extruder separate file for sensor holder is correct.](/images/thumb/9/9a/D3D-Universal-Axis-2019.12.14.png/120px-D3D-Universal-Axis-2019.12.14.png)

![[10] Motor Side of Axis - 221k - FreeCAD -File:Universal axis motor side.fcstd. STL - File:Universal axis motor side.stl](/images/thumb/4/45/Motorside.jpg/120px-Motorside.jpg)

![[10] Short Idler Side - 75k - FreeCAD - File:Universal Axis Idler Side short version.fcstd. STL - File:Universal Axis Idler Side short version.stl.](/images/thumb/a/ae/Idlershort.jpg/120px-Idlershort.jpg)

![[10] Belt Holding Peg - FreeCAD original size - File:Peg 8mm rods.fcstd. STL at 85% size, works well - File:Peg 8mm rods.stl](/images/thumb/a/a5/Peg85.jpg/120px-Peg85.jpg)

![Simple Extruder WIP. Github - [2]. Gitlab - [https://gitlab.com/marcin_ose/d3d-universal.](/images/thumb/5/59/CC_simple_extruder_dev_03NOV2019.png/120px-CC_simple_extruder_dev_03NOV2019.png)

![Extruder Spring for Simple Extruder. Buy + spec - [3]. FreeCAD file - File:Extruderspring.fcstd](/images/thumb/7/79/Extruderspring.png/120px-Extruderspring.png)

![Extruder assembly - Gitlab - [4]. FreeCAD - File:Simpleextruderassy.fcstd](/images/thumb/2/2b/Finalextruder.png/120px-Finalextruder.png)

![Main extruder part. - Gitlab - [5]. FreeCAD - File:Mainextruderpart.fcstd. STL - File:Extruder main.stl](/images/thumb/c/c8/Mainextruderpart.png/120px-Mainextruderpart.png)

![3 mm heat break.File:3heatbreak.fcstd. Re-Source - [6]](/images/thumb/5/5c/3heatbreak.png/120px-3heatbreak.png)

![RAMPS 1.4 - FreeCAD -File:RAMPS14 v1904.fcstd. Full detailed file - 4MB - [7]](/images/thumb/a/a5/RAMPS14_v1904.png/120px-RAMPS14_v1904.png)

![Stepper driver - FreeCAD -File:Stepperdriver v1904.fcstd. File for detailed LCD controller and endstop can be found at [8]](/images/thumb/a/a8/Stepperdriver_v1904.png/120px-Stepperdriver_v1904.png)

![Solid state relay - FreeCAD -File:Ssr v1904.fcstd. Source: [9]. See Fotek SSR. Dimensions verified with Amazon source.](/images/thumb/b/ba/Ssr_v1904.png/120px-Ssr_v1904.png)

![Reprap Discount Smart Controller - FreeCAD -File:Smartcontroller v1904.fcstd. Source: [10].](/images/thumb/f/fe/Smartcontroller_v1904.png/120px-Smartcontroller_v1904.png)

![Ground Fault Connection Interrupt (GFCI) outlet - FreeCAD -File:Gfci v1904.fcstd. CAD source at McMaster Carr: [11]. May not represent actual GFCI.](/images/thumb/5/50/Gfci_v1904.png/117px-Gfci_v1904.png)

![D3D Universal with 3D printer motor functioning as a CNC mill. - FreeCAD -[12] or Michel's repo.](/images/thumb/6/6e/D3duniversalmill.png/120px-D3duniversalmill.png)

![D3D Universal with plotter attachment. - See D3D Universal Plotter by Ferdi Meier. Gitlab - [13]](/images/thumb/8/88/D3Duniversalplotter1.jpg/120px-D3Duniversalplotter1.jpg)

![Electric Motor. Michel Repo - [14]. Assembly in FreeCAD, Marcin's Repo - [15]](/images/thumb/5/58/Electricmotor.png/120px-Electricmotor.png)