Universal Power Supply/Research Development

| Universal Power Supply | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

The universal power supply contains the power electronics and power supplies for:

- Welders

- Plasma Cutters

- Battery Chargers

- Induction Furnaces

- CO2 Laser Cutters

- Stepper Motors

- Charge Controllers

Applications

- Powering welders, plasma cutters, battery chargers, induction furnaces, CO2 laser cutters

- Inverters for household power from batteries

- Voltage regulation/conditioning to get grid-quality power from variable power sources such as windmills, steam engines (especially solar powered)

- Battery charging from windmills, steam engines

(the other mechanical components of the above devices are covered as separate tools of the GVCS)

Physical Dimensions

As an example, the Zapp Star 1000 Nickel-Iron Battery is listed as 15" x 6" x 20". Ten of these for a 12 volt battery with 1000Ah would require 10.4 cubic feet with an approximate weight of 1400 pounds (using similar BeUtilityFree specs). This is not man-portable. Scaling down to 12 volts at 100Ah reduces the dimensions to 1.5 cubic feet and 150 pounds. Build ten of these and you can wire them in parallel to increase work time or in series to increase voltage (which may be advantageous in charging). Assume roughly 1.5 cubic feet 150 pound 12 volt 100Ah battery cube.

What are the dimensions of hydraulic power cube? Use the same cube frame?

Other specifications

- Scalability via modular add-on

- Quick disconnect components wherever possible

- Logic circuits millable with basic CNC Circuit Mill

- Insulators printable with 3D Printer or Ceramic 3D Printer

- Ability to operate with any voltage from a few volts to 1kV

- Ability to generate any frequency

- Open Source Enclosure - enclosure design that allows maximum scalability and flexibility

- Design for flexible fabrication via Open Source Fab Lab, initially using off-shelf components

In practice, the above will be implemented by refining one functionality after another, and adding modules that will allow for different functions and scales.

We're interested in a universal, modular power conversion device for electricity. I am talking about different modules that can be plugged together for something like a Lego Set of power electronics. Each module would in itself be modular, so it can consist of a number of units connected for scaling current or voltage.

Modules

- 50/60 hz electricity at common voltages such as 110 or 230 or 440

- DC current for plasma cutters or welders

- Battery charge-controller current

- High frequency power for induction furnaces

- Regulation of variable voltage (say 60-230 v AC) to charge batteries

- DC-DC conversion.

- Synchronous inverter so that multiple units can be stacked for applications that require higher current

That just about covers all power devices for advanced civilization, more or less.

Design Path

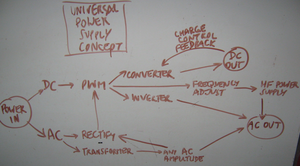

The general scheme would be to: (1) rectify a typically oscillating input from some power generating device, if it's not DC already, (2) chop it up, (3) scale it, (4) form it, (5) and finally, spit it out as DC or AC.

We want to create a universal switched mode power supply kit, with some power conditioning and regulation.

Please propose a basic starting circuit with the following specs: (1) Takes any AC input (from an ac generator) to either battery storage or an inverter/converter. (2) Specify parts for a system that can runs from 100W to about 20kW for starters. Is this feasible, or is the problem statement ill-defined?

After the above, we'd have to go to 3-phase converters, since many appliances of interest (such as induction furnaces) run off 3-phase.

See also