Metal Roller/Research Development: Difference between revisions

Jump to navigation

Jump to search

Matt Maier (talk | contribs) |

|||

| (2 intermediate revisions by 2 users not shown) | |||

| Line 6: | Line 6: | ||

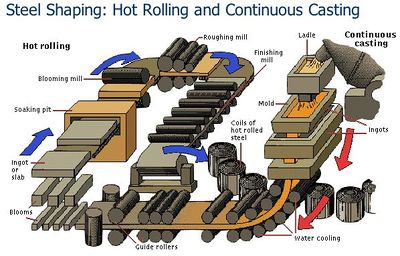

[[Image:Hotrolling.jpg|thumb|400px|right|Hot Rolling]] | [[Image:Hotrolling.jpg|thumb|400px|right|Hot Rolling]] | ||

=Tech Tree of Choices= | |||

Rolling can take several forms - no pun intended. Rolling of flat sheets is typical. Rolling of threads can likewise be done via heavy hydralics and thread dies. This appears to be a favorable process for threading due to its speed and accuracy. | |||

*See thread rolling machines - [http://www.leistritzcorp.com/machine_tools.cfm] | |||

*The alternative to rolling for threads is a screw machine, or a whirling machine - [https://www.youtube.com/watch?v=jQ2Ted8Ydus] | |||

=Ideas= | |||

* It seems likely that the metal rollers will need to be carved out of large castings on a lathe in order to be smooth and solid. In order to avoid the need for a lathe during construction it might be possible to use the machine itself as an in place lathe by temporarily rigging the roller drive system for high speed and mounting a cutting bit. --[[User:Tristan Hume|Tristan Hume]] ([[User talk:Tristan Hume|talk]]) 03:59, 28 January 2015 (CET) | |||

=Next steps= | =Next steps= | ||

Latest revision as of 15:25, 10 March 2018

| Metal Roller | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

Research for the Metal Roller.

Tech Tree of Choices

Rolling can take several forms - no pun intended. Rolling of flat sheets is typical. Rolling of threads can likewise be done via heavy hydralics and thread dies. This appears to be a favorable process for threading due to its speed and accuracy.

- See thread rolling machines - [1]

- The alternative to rolling for threads is a screw machine, or a whirling machine - [2]

Ideas

- It seems likely that the metal rollers will need to be carved out of large castings on a lathe in order to be smooth and solid. In order to avoid the need for a lathe during construction it might be possible to use the machine itself as an in place lathe by temporarily rigging the roller drive system for high speed and mounting a cutting bit. --Tristan Hume (talk) 03:59, 28 January 2015 (CET)

Next steps

- search the wiki for metal rolling pages

- grab links from youtube, google, and wikipedia for relevant information.

- Classify metal rolling techniques

- identify industry standard designs/manufacturers

- evaluate designs against OSE Spec

- formulate design for CAD team

- etc...

Research

- This is a great introductory article on the design of roll forming machines by Chuck Summerhill of Roll-Kraft. File:Basic Roll Design.pdf

See Also