Global Village Construction Set: Difference between revisions

No edit summary |

|||

| (236 intermediate revisions by 30 users not shown) | |||

| Line 1: | Line 1: | ||

{{RequiredReading}} | |||

{{OrigLang}} | |||

{{ | {{TED Talk}} | ||

=Original Definition = | |||

The '''[[Global Village Construction Set]]''' (GVCS) is a modular, DIY, low-cost set of blueprints that enables fabrication of the 50 different Industrial Machines that it takes to build a small, sustainable civilization with modern comforts. The name, GVCS, has been coined for the first time in 2008 - at a lecture at the University of Missouri, Columbia - see [[UM Presentation]]. | |||

=Value= | |||

The combined value of production (current market size) of the 50 different GVCS machines is approximately $11T. This accounts for the goods and services that can be produced by the GVCS machines - based on existing production volume of the goods and services that the 50 GVCS machines can address. | |||

=Definition Evolution - GVCS 2.0 and GVCS 3.0= | |||

The original definition still applies, with more specifications added. Note that we are aiming for GVCS 1.0 by 2028. | |||

#'''A set of fundamental technologies sufficient to build a thriving economy anywhere in the world.''' This implies that the the set must be proven to allow efficient production of food, shelter, consumer goods, cars, fuel, and other goods - except for exotic imports (coffee, bananas, advanced semiconductors in the initial phases of GVCS). This is included in GVCS 1.0. | |||

#'''Reality check on the development cost''' of each product, estimated based on current experience to be roughly $1M per product for a total development budget need of $50M by 2028. For example, the Seed Eco-Home development cost to present has been about $1M, and we expect a similar figure to obtain for other technologies. The expected cost of first prototypes is on the order of $10k, but multiple prototypes are needed. Further, production engineering can easily cost 10x the initial prototype, and enterprise model development adds another factor of 10x - for a rough budget of $1M for economically competitive products that become candidates for [[Distributed Market Substitution]]. Given an essential absence of [[Collaborative Literacy]] throughout the world and financial pressure to make a living, OSE does not have sufficient infrastructure to allow for scaling of a Linux-style development effort, because the material costs and coordination costs are prohibitive. This Linux-style development infrastructure still remains our goal, but we don't see it becoming realized without significant capital investment into physical plant. | |||

#'''GVCS 2.0''' -Each 'product' must be expanded to its fuller product ecology in terms of both [[Recursion]] and [[Modular Product Ecosystems]]. For example, for the humble ''cement mixer'' - we are now expanding to distributed [[Solar Concrete]] production (recursion in terms of material feedstocks) and application to [[Seed Eco-Home 4]] for foundations, driveways, stabilized [[CEB]] production, hardscapes, countertops, roof shingles, polished concrete, among others. We are aiming for GVCS 2.0 within 1-2 years of GVCS 1.0. This relies on rapid scaling via modular enterprise replication at the point that GVCS 1.0 is completed, and significant financial feedback loops are created. | |||

#'''GVCS Opportunity''' - the scalable, open, modular design language for product ecosystems appears to be working at present - and working better than expected. The downside is that it takes much more effort to design such a product ecology, and thus much more time to teach it. Thus our product development programs now center on a 4 year program, not one month [[Dedicated Project Visits]] which were begun in 2009. The new development route allows for the continuity required to first, learn core aspects of [[OSE Culture]] and [[Collaborative Literacy]], and engage in the due diligence to achieve [[Immortality]] in any undertaking. This is consistent with general principles of [[Time Binding]]. | |||

#'''GVCS 3.0''' is open-sourcing of the entire [[Technosphere]], in the broad sense. This means that collaborative development has been normalized, patents have been eradicated, trade secrets are a rare occurrence. This also means that global instability has been significantly reduced by making self-determination accessible to all via financial independence, and global moral intelligence has increased greatly as integrated education becomes accessible to everyone. Incentives for rogue actors, dictatorial behavior, and other evil have been reduced to a minimum. We expect this transition to happen around 10 years from GVCS 2.0, and occurring within a similar timeframe as the [[Singularity]]. We aim for collaborative culture to enter before the singularity, otherwise the threat of evil AI dominating remains real. The battle is ongoing. | |||

=End State= | |||

The above paragraph is a brief summary, but the goals of the GVCS are much larger. In 2019, our [[Vision]] has been reframed to '''collaborative design for a transparent and inclusive economy of abundance'''. The GVCS remains at the center of that. However, one cannot build sound technology without building sound people. Open, transparent collaboration includes developing the human aspect - in terms of soft skills to collaborate, be vulnerable, have self-esteem, have a growth mindset - the soft requirements for any [[Super-Cooperator]]. OSE strives to produce [[Integrated Humans]] who have both the hard and soft skills to make a better world - as movement entrepreneurs whose life revolves around solving pressing world issues. | |||

Currently there are several, outstanding, unconscionable aspects of civilization: continuing ecocide, war, consumerism, poverty, poor distribution of wealth or access, ignorance - see [[Pressing World Issues]]. The world has improved to more liberty for more people, but many are left behind. These are easily solvable by taking on a fundamental approach, such as planting trees, open-sourcing the economy, and learning to grow as humans. These solutions are very easy and very hard at the same time. | |||

At the core, OSE's work requires human evolution for a transition from a proprietary, military economy - to a collaborative economy. | |||

With great power comes great responsibility. ''Economy of abundance'' in our vision statement is a rigorous requirement that implies wisdom towards efficient production of basic needs, as a basis for [[Self-Determination]]. | |||

'''When exactly do we say that the Global Village Construction Set is complete - that we have succeeded?''' It is when: | |||

#All the 50 technologies of the [[GVCS]] are finished, to the point of economically-feasible business models being developed for each machine or product ecology of machines. Further, derivative industry is open source, such as materials production - which is a derivative of the productive capacity of the 50 GVCS machines. For example, the CNC multimachine can make motors which can make vacuum pumps, which combined with construction equipment can make clean rooms for making semiconductors or medical equipment. | |||

#Anyone has access to build any product anywhere in an open source microfactory, which is powered by a repository of global, collaborative design and open source production tools. This means that any place in the world has a realistic capacity to create a modern economy if it chooses to do so, without having to make compromises of a typical [[Technology Colony]]. | |||

#All infrastructure-building tools to start villages, micro-states, farms, factories, civil works, land restoration operations, and any other human infrastructure - can be built at low cost using best-practice, open source techniques and equipment. | |||

#We have succeeded in implementing a globally-distributed teaching infrastructure for regenerative enterprise. Hundreds of land-based, OSE facilities are built around the world - as land-based campuses somewhat like a university campus - which are fully regenerative global villages that thrive in harmony with their natural life support systems. These are places of real life, learning, and activism - with an explicit purpose of solving pressing world issues. Imagine going to college, where as a result - you end up not as a quant or symbolic analyst in a cubicle - but as a hands-on builder of a new world: a person who leaves college pursuing solutions to pressing world issues, and getting involved in a full time-effort of such transformation. Why the OSE campuses? Because sometimes transformative work has no money in it. The status quo does not pay change-makers to subvert itself. So the OSE Campus is a facility where people contribute 2 hours of work per day to guarantee thriving based on physical needs, and the rest of the time is spent in pursuit of self-determination. See [[Open Source Philosophy]] video for the 2 Hours of Work Per Day, whether it's people in huts like Marcin in 2006, or people in [[Seed Eco-Homes]] or Eco-Mansions. | |||

#Numbers-wise, [[Distributed Market Substitution]] is growing as an exponential occurrence, with billions worth of markets already substituted on 3-year timescales. | |||

#A large number of people are trained in [[Collaborative Literacy]], and thus engage in open source product development as the new norm - about 10% of all human enterprise across sectors (mining, manufacturing, governance, financial, agriculture, services). Open publishing is the norm. | |||

#Mass creation of right livelihood has begun in earnest, and people have a fair chance to do what they love for a living | |||

#Modular, open source standards are common, such that planned obsolescence - as occurring by virtue of black-boxing, self-destruct parts, changed form factors, proprietary software, non-interchangeable parts, hard to find parts, expensive parts, design-for-non-disassembly, easily-breakable parts, inferior materials, and others - are design, and other bad design - has ceased to be a dominant factor in one's [[Cost of Living]]. | |||

#All pressing world issues mentioned above are in being solved in significant ways (such as [[Gini Coefficient]] rising at least to pre-industrial levels), species extinction ended, clean energy provided to all, [[Fab Cities]] as the new norm, as general self-determination replaces current alienation of people from themselves, from others, and from nature. | |||

#We envision a life where a 'job' is replaced by 'living fully' (while 'making a living'). Where the office cubicle is replaced by your home office. Where manufacturing as we know it is replaced by microfactories and Fab City. Where people pursue self-determination (autonomy, mastery, purpose - which assumes unleashed innovation and creativity). And where the massive gaps between the haves and have-nots have been replaced by open access. Where institution of power concentration have been replaced by institutions of open collaboration. Where fear is replaced by love. Where selfishness is replaced by connectedness. Where the rigorous condition of abundance has replaced scarcity thinking. Where the cookie cutter urban sprawl has been replaced by regenerative design that includes nature. Where a throwaway, consumer society has been replaced by a producer mentality and lifetime design. Where if you want to get a car, you can build one at your local microfactory to meet your exact needs, guided by your friendly teaching staff - or you can at least participate as much as you like (from 0 to fully) in its production. On first principles, this is all inevitable in a [[Kardashev Scale]] <1 earthling civilization - there is plenty of energy - about 10,000 times more energy comes from the sun to the Earth than civilization uses today.. | |||

= | =Introduction= | ||

Marcin Jakubowski explains the Global Village Construction Set in his TED Talk. | |||

Can't see the video below? Try: http://www.ted.com/talks/marcin_jakubowski.html | |||

(https://www.youtube.com/watch?v=S63Cy64p2lQ) | |||

<html><div style="max-width:854px"><div style="position:relative;height:0;padding-bottom:56.25%"><iframe src="https://embed.ted.com/talks/marcin_jakubowski" width="854" height="480" style="position:absolute;left:0;top:0;width:100%;height:100%" frameborder="0" scrolling="no" allowfullscreen></iframe></div></div></html> | |||

Want to know more? Explore the [[Global_Village_Construction_Set|Global Village Construction Set tech tree]]. | |||

Want to contribute? Sign up for [[OSEmail]] to get monthly updates. | |||

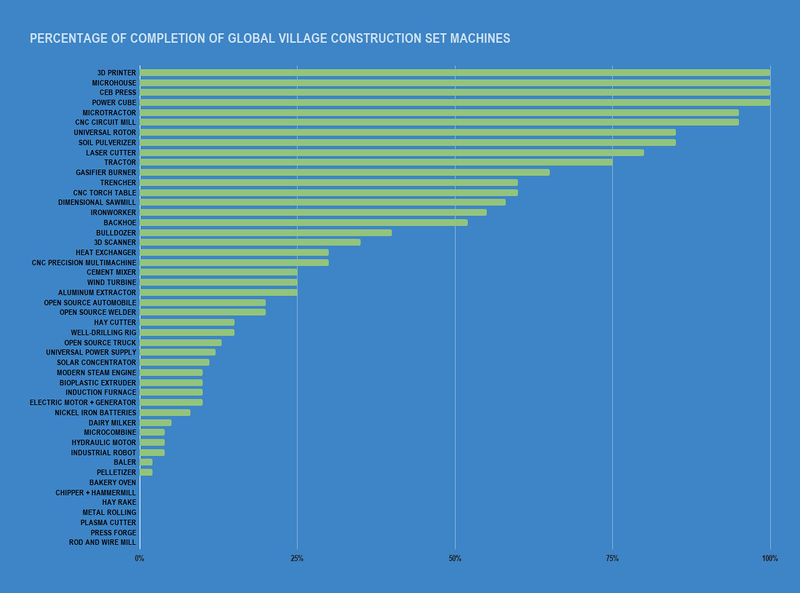

=Completion Status= | |||

[[Image:completionstatus2018.jpg|800px]] | |||

See [[GVCS_State_of_Completion]] for the history of the completion status. | |||

[https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0AkNG-lv1ELQvdGYycGFSMjYtODlZcFROcHZ2NjBwNEE&usp=drive_web#gid=3 edit] | |||

=Prototypes - Visual Status= | |||

Items prototyped are in red. State in 2018. | |||

<html><iframe src="https://docs.google.com/presentation/d/e/2PACX-1vSSjK5xqiNRMCLF6tu4goP9bnc9Kt1RRlNRHmwXQEIx2cocOSEqB9H5-04ZofALogRnsmYLtbLrU4L1/embed?start=false&loop=false&delayms=3000" frameborder="0" width="960" height="569" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | |||

[https://docs.google.com/presentation/d/1eSsI59MppMhLLDyBoN90T7vasJPmgK0iBBgWxtg5aZ8/edit#slide=id.g4071900322_0_32 edit] | |||

[ | =Timeline= | ||

(needs updating since 2014 - see [https://www.opensourceecology.org/product-releases/ blog] or [ FB] for updates. | |||

The Open Source Ecology experiment was formulated in 2003. The practical experiment began on a 5 acre parcel on the outskirts of Madison, Wisconsin, USA. Networking with early collaborators, the project found its new home on a 20 acre parcel in Osborn, Missouri. In 2006, the project moved to its permanent location in Maysville, Missouri - to Factor e Farm - birthplace of the Global Village Construction Set. | |||

= | <html><iframe src="https://cdn.knightlab.com/libs/timeline/latest/embed/index.html?source=0AkNG-lv1ELQvdEMxdzRnU2VFbUllZ2Y0cnZPRld3SXc&font=Bevan-PotanoSans&maptype=toner&lang=en&hash_bookmark=true&start_at_slide=23&height=650" width="100%" height="650" frameborder="0"></iframe></html> | ||

= Media = | |||

See '''[[GVCS TED Talk]] | |||

= | {| | ||

|<html> | |||

<!--copy and paste--><object width="600" height="400"><param name="movie" value="http://video.ted.com/assets/player/swf/EmbedPlayer.swf"></param><param name="allowFullScreen" value="true" /><param name="allowScriptAccess" value="always"/><param name="wmode" value="transparent"></param><param name="bgColor" value="#ffffff"></param> <param name="flashvars" value="vu=http://video.ted.com/talk/stream/2011U/Blank/MarcinJakubowski_2011U-320k.mp4&su=http://images.ted.com/images/ted/tedindex/embed-posters/MarcinJakubowski-2011U.embed_thumbnail.jpg&vw=510&vh=300&ap=0&ti=1122&lang=eng&introDuration=15330&adDuration=4000&postAdDuration=830&adKeys=talk=marcin_jakubowski;year=2011;theme=the_rise_of_collaboration;theme=new_on_ted_com;theme=tales_of_invention;theme=design_like_you_give_a_damn;event=Design+Like+You+Give+a+Damn;tag=Culture;tag=Technology;tag=open-source;tag=ted+fellows;&preAdTag=tconf.ted/embed;tile=1;sz=512x300;" /><embed src="http://video.ted.com/assets/player/swf/EmbedPlayer.swf" pluginspace="http://www.macromedia.com/go/getflashplayer" type="application/x-shockwave-flash" wmode="transparent" bgColor="#ffffff" width="600" height="400" allowFullScreen="true" allowScriptAccess="always" flashvars="vu=http://video.ted.com/talk/stream/2011U/Blank/MarcinJakubowski_2011U-320k.mp4&su=http://images.ted.com/images/ted/tedindex/embed-posters/MarcinJakubowski-2011U.embed_thumbnail.jpg&vw=510&vh=300&ap=0&ti=1122&lang=eng&introDuration=15330&adDuration=4000&postAdDuration=830&adKeys=talk=marcin_jakubowski;year=2011;theme=the_rise_of_collaboration;theme=new_on_ted_com;theme=tales_of_invention;theme=design_like_you_give_a_damn;event=Design+Like+You+Give+a+Damn;tag=Culture;tag=Technology;tag=open-source;tag=ted+fellows;"></embed></object> | |||

</html> | |||

|<html><iframe src="https://player.vimeo.com/video/16106427" width="600" height="400" frameborder="0"></iframe></html> | |||

|} | |||

== Key Features == | |||

{| | |||

| '''See summary at [[OSE Specifications for Product Design]].''' | |||

*'''[[Open Hardware|Open Source]]''' - we freely publish our 3d designs, schematics, instructional videos, budgets, and product manuals on our open source wiki and we harness open collaboration with technical contributors. | |||

[[ | *'''[[OSE Spec|Low-Cost]]''' - The cost of making or buying our machines is, on average, 8x cheaper than buying from an Industrial Manufacturer, including an average labor cost of hour for a GVCS fabricator. | ||

*'''[[Product Ecologies|Modular]]''' - Motors, parts, assemblies, and power units can interchange, where units can be grouped together to diversify the functionality that is achievable from a small set of units. | |||

*'''[[OSE Spec|User-Serviceable]]''' - Design-for-disassembly allows the user to take apart, maintain, and fix tools readily without the need to rely on expensive repairmen. | |||

*'''[[RepLab|DIY]]''' - (do-it-yourself) The user gains control of designing, producing, and modifying the GVCS tool set. | |||

*'''[[Product Ecology|Closed Loop Manufacturing]]''' - Metal is an essential component of advanced civilization, and our platform allows for recycling metal into virgin feedstock for producing further GVCS technologies - thereby allowing for cradle-to-cradle manufacturing cycles | |||

*'''[[OSE Spec|High Performance]]''' - Performance standards must match or exceed those of industrial counterparts for the GVCS to be viable. | |||

*'''[[Flexible Fabrication]]''' - It has been demonstrated that the flexible use of generalized machinery in appropriate-scale production is a viable alternative to centralized production. | |||

*'''[[Distributive Economics]]''' - We encourage the replication of enterprises that derive from the GVCS platform as a route to truly free enterprise - along the ideals of Jeffersonian democracy. | |||

*'''[[OSE Spec|Industrial Efficiency]]''' - In order to provide a viable choice for a resilient lifestyle, the GVCS platform matches or exceeds productivity standards of industrial counterparts. | |||

|[[Image:GVCS.jpg|600px|The Global Village Construction Set]] | |||

''' | |} | ||

[[Image: | |||

The | |||

== GVCS Machines == | |||

''See main article [[GVCS Machine]]'' | |||

OSE is developing 50 machines of the Global Village Construction Set via module-based design. This means that we break machines down into modules, and each module can be developed in parallel with other modules. Examples are [[CEB Press]] or [[Tractor]]. | |||

The | The exact list of GVCS machines has evolved over time and is still subject to change. For example, while the [[MicroHouse]] and the [[Car]] are not GVCS machines in a strict sense (but products created by GVCS machines), they are treated as GVCS machines for historical and business-oriented reasons. | ||

Documentation is found at different places for different target groups: | |||

* Graphical list of 50 machines on our [http://opensourceecology.org/gvcs/ main website] (Public) | |||

* Hierarchical representation of machines/modules at dozuki: http://opensourceecology.dozuki.com/ (Public, Prototypers, Developers) | |||

* Wiki internal list of GVCS machines and their breakdown into modules - [[GVCS Machines and Modules]] and [[GVCS State of Completion]] (Prototypers, Developers) | |||

{{GVCS_List}} | |||

== | == See Also == | ||

* [http://makeprojects.com/Area/Open_Source_Ecology Build Instructions on Make Projects] | |||

* [[GVCS Archive]] | |||

* [[GVCS List]] | |||

* [[Marketing]] | |||

* [[Media]] | |||

* [[Press]] | |||

* [[Subject Matter Expert]] | |||

[[Category: | [[Category: GVCS]] | ||

Latest revision as of 18:30, 17 September 2025

| OSE Required Reading | |||

|---|---|---|---|

| Wiki instructions · Crash course on OSE · Global Village Construction Set · Getting Started Guide · Team Culturing · Version control - Genealogies | |||

Original Definition

The Global Village Construction Set (GVCS) is a modular, DIY, low-cost set of blueprints that enables fabrication of the 50 different Industrial Machines that it takes to build a small, sustainable civilization with modern comforts. The name, GVCS, has been coined for the first time in 2008 - at a lecture at the University of Missouri, Columbia - see UM Presentation.

Value

The combined value of production (current market size) of the 50 different GVCS machines is approximately $11T. This accounts for the goods and services that can be produced by the GVCS machines - based on existing production volume of the goods and services that the 50 GVCS machines can address.

Definition Evolution - GVCS 2.0 and GVCS 3.0

The original definition still applies, with more specifications added. Note that we are aiming for GVCS 1.0 by 2028.

- A set of fundamental technologies sufficient to build a thriving economy anywhere in the world. This implies that the the set must be proven to allow efficient production of food, shelter, consumer goods, cars, fuel, and other goods - except for exotic imports (coffee, bananas, advanced semiconductors in the initial phases of GVCS). This is included in GVCS 1.0.

- Reality check on the development cost of each product, estimated based on current experience to be roughly $1M per product for a total development budget need of $50M by 2028. For example, the Seed Eco-Home development cost to present has been about $1M, and we expect a similar figure to obtain for other technologies. The expected cost of first prototypes is on the order of $10k, but multiple prototypes are needed. Further, production engineering can easily cost 10x the initial prototype, and enterprise model development adds another factor of 10x - for a rough budget of $1M for economically competitive products that become candidates for Distributed Market Substitution. Given an essential absence of Collaborative Literacy throughout the world and financial pressure to make a living, OSE does not have sufficient infrastructure to allow for scaling of a Linux-style development effort, because the material costs and coordination costs are prohibitive. This Linux-style development infrastructure still remains our goal, but we don't see it becoming realized without significant capital investment into physical plant.

- GVCS 2.0 -Each 'product' must be expanded to its fuller product ecology in terms of both Recursion and Modular Product Ecosystems. For example, for the humble cement mixer - we are now expanding to distributed Solar Concrete production (recursion in terms of material feedstocks) and application to Seed Eco-Home 4 for foundations, driveways, stabilized CEB production, hardscapes, countertops, roof shingles, polished concrete, among others. We are aiming for GVCS 2.0 within 1-2 years of GVCS 1.0. This relies on rapid scaling via modular enterprise replication at the point that GVCS 1.0 is completed, and significant financial feedback loops are created.

- GVCS Opportunity - the scalable, open, modular design language for product ecosystems appears to be working at present - and working better than expected. The downside is that it takes much more effort to design such a product ecology, and thus much more time to teach it. Thus our product development programs now center on a 4 year program, not one month Dedicated Project Visits which were begun in 2009. The new development route allows for the continuity required to first, learn core aspects of OSE Culture and Collaborative Literacy, and engage in the due diligence to achieve Immortality in any undertaking. This is consistent with general principles of Time Binding.

- GVCS 3.0 is open-sourcing of the entire Technosphere, in the broad sense. This means that collaborative development has been normalized, patents have been eradicated, trade secrets are a rare occurrence. This also means that global instability has been significantly reduced by making self-determination accessible to all via financial independence, and global moral intelligence has increased greatly as integrated education becomes accessible to everyone. Incentives for rogue actors, dictatorial behavior, and other evil have been reduced to a minimum. We expect this transition to happen around 10 years from GVCS 2.0, and occurring within a similar timeframe as the Singularity. We aim for collaborative culture to enter before the singularity, otherwise the threat of evil AI dominating remains real. The battle is ongoing.

End State

The above paragraph is a brief summary, but the goals of the GVCS are much larger. In 2019, our Vision has been reframed to collaborative design for a transparent and inclusive economy of abundance. The GVCS remains at the center of that. However, one cannot build sound technology without building sound people. Open, transparent collaboration includes developing the human aspect - in terms of soft skills to collaborate, be vulnerable, have self-esteem, have a growth mindset - the soft requirements for any Super-Cooperator. OSE strives to produce Integrated Humans who have both the hard and soft skills to make a better world - as movement entrepreneurs whose life revolves around solving pressing world issues.

Currently there are several, outstanding, unconscionable aspects of civilization: continuing ecocide, war, consumerism, poverty, poor distribution of wealth or access, ignorance - see Pressing World Issues. The world has improved to more liberty for more people, but many are left behind. These are easily solvable by taking on a fundamental approach, such as planting trees, open-sourcing the economy, and learning to grow as humans. These solutions are very easy and very hard at the same time.

At the core, OSE's work requires human evolution for a transition from a proprietary, military economy - to a collaborative economy.

With great power comes great responsibility. Economy of abundance in our vision statement is a rigorous requirement that implies wisdom towards efficient production of basic needs, as a basis for Self-Determination.

When exactly do we say that the Global Village Construction Set is complete - that we have succeeded? It is when:

- All the 50 technologies of the GVCS are finished, to the point of economically-feasible business models being developed for each machine or product ecology of machines. Further, derivative industry is open source, such as materials production - which is a derivative of the productive capacity of the 50 GVCS machines. For example, the CNC multimachine can make motors which can make vacuum pumps, which combined with construction equipment can make clean rooms for making semiconductors or medical equipment.

- Anyone has access to build any product anywhere in an open source microfactory, which is powered by a repository of global, collaborative design and open source production tools. This means that any place in the world has a realistic capacity to create a modern economy if it chooses to do so, without having to make compromises of a typical Technology Colony.

- All infrastructure-building tools to start villages, micro-states, farms, factories, civil works, land restoration operations, and any other human infrastructure - can be built at low cost using best-practice, open source techniques and equipment.

- We have succeeded in implementing a globally-distributed teaching infrastructure for regenerative enterprise. Hundreds of land-based, OSE facilities are built around the world - as land-based campuses somewhat like a university campus - which are fully regenerative global villages that thrive in harmony with their natural life support systems. These are places of real life, learning, and activism - with an explicit purpose of solving pressing world issues. Imagine going to college, where as a result - you end up not as a quant or symbolic analyst in a cubicle - but as a hands-on builder of a new world: a person who leaves college pursuing solutions to pressing world issues, and getting involved in a full time-effort of such transformation. Why the OSE campuses? Because sometimes transformative work has no money in it. The status quo does not pay change-makers to subvert itself. So the OSE Campus is a facility where people contribute 2 hours of work per day to guarantee thriving based on physical needs, and the rest of the time is spent in pursuit of self-determination. See Open Source Philosophy video for the 2 Hours of Work Per Day, whether it's people in huts like Marcin in 2006, or people in Seed Eco-Homes or Eco-Mansions.

- Numbers-wise, Distributed Market Substitution is growing as an exponential occurrence, with billions worth of markets already substituted on 3-year timescales.

- A large number of people are trained in Collaborative Literacy, and thus engage in open source product development as the new norm - about 10% of all human enterprise across sectors (mining, manufacturing, governance, financial, agriculture, services). Open publishing is the norm.

- Mass creation of right livelihood has begun in earnest, and people have a fair chance to do what they love for a living

- Modular, open source standards are common, such that planned obsolescence - as occurring by virtue of black-boxing, self-destruct parts, changed form factors, proprietary software, non-interchangeable parts, hard to find parts, expensive parts, design-for-non-disassembly, easily-breakable parts, inferior materials, and others - are design, and other bad design - has ceased to be a dominant factor in one's Cost of Living.

- All pressing world issues mentioned above are in being solved in significant ways (such as Gini Coefficient rising at least to pre-industrial levels), species extinction ended, clean energy provided to all, Fab Cities as the new norm, as general self-determination replaces current alienation of people from themselves, from others, and from nature.

- We envision a life where a 'job' is replaced by 'living fully' (while 'making a living'). Where the office cubicle is replaced by your home office. Where manufacturing as we know it is replaced by microfactories and Fab City. Where people pursue self-determination (autonomy, mastery, purpose - which assumes unleashed innovation and creativity). And where the massive gaps between the haves and have-nots have been replaced by open access. Where institution of power concentration have been replaced by institutions of open collaboration. Where fear is replaced by love. Where selfishness is replaced by connectedness. Where the rigorous condition of abundance has replaced scarcity thinking. Where the cookie cutter urban sprawl has been replaced by regenerative design that includes nature. Where a throwaway, consumer society has been replaced by a producer mentality and lifetime design. Where if you want to get a car, you can build one at your local microfactory to meet your exact needs, guided by your friendly teaching staff - or you can at least participate as much as you like (from 0 to fully) in its production. On first principles, this is all inevitable in a Kardashev Scale <1 earthling civilization - there is plenty of energy - about 10,000 times more energy comes from the sun to the Earth than civilization uses today..

Introduction

Marcin Jakubowski explains the Global Village Construction Set in his TED Talk.

Can't see the video below? Try: http://www.ted.com/talks/marcin_jakubowski.html (https://www.youtube.com/watch?v=S63Cy64p2lQ)

Want to know more? Explore the Global Village Construction Set tech tree.

Want to contribute? Sign up for OSEmail to get monthly updates.

Completion Status

See GVCS_State_of_Completion for the history of the completion status.

Prototypes - Visual Status

Items prototyped are in red. State in 2018.

Timeline

(needs updating since 2014 - see blog or [ FB] for updates.

The Open Source Ecology experiment was formulated in 2003. The practical experiment began on a 5 acre parcel on the outskirts of Madison, Wisconsin, USA. Networking with early collaborators, the project found its new home on a 20 acre parcel in Osborn, Missouri. In 2006, the project moved to its permanent location in Maysville, Missouri - to Factor e Farm - birthplace of the Global Village Construction Set.

Media

See GVCS TED Talk

Key Features

See summary at OSE Specifications for Product Design.

|

|

GVCS Machines

See main article GVCS Machine

OSE is developing 50 machines of the Global Village Construction Set via module-based design. This means that we break machines down into modules, and each module can be developed in parallel with other modules. Examples are CEB Press or Tractor.

The exact list of GVCS machines has evolved over time and is still subject to change. For example, while the MicroHouse and the Car are not GVCS machines in a strict sense (but products created by GVCS machines), they are treated as GVCS machines for historical and business-oriented reasons.

Documentation is found at different places for different target groups:

- Graphical list of 50 machines on our main website (Public)

- Hierarchical representation of machines/modules at dozuki: http://opensourceecology.dozuki.com/ (Public, Prototypers, Developers)

- Wiki internal list of GVCS machines and their breakdown into modules - GVCS Machines and Modules and GVCS State of Completion (Prototypers, Developers)