CEB Press: Difference between revisions

No edit summary |

|||

| (495 intermediate revisions by 34 users not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{Hint|Last updated Jan 2018}} | ||

-- | [http://opensourceecology.org/wiki/CEB_Press_6_-_Overall_Machine_-_Development_Board Link to CEB Press Build June 2015] | ||

{{OrigLang}} | |||

<html><iframe src="https://player.vimeo.com/video/49864277" width="500" height="281" frameborder="0" webkitAllowFullScreen mozallowfullscreen allowFullScreen></iframe> <p><a href="http://vimeo.com/49864277">The CEB Story 2012.</a> from <a href="http://vimeo.com/opensourceecology">Open Source Ecology</a> on <a href="http://vimeo.com">Vimeo</a>.</p></html> | |||

{{GVCS Header}} | |||

# | =Overview= | ||

# | |||

[[File:Machine.jpg|right|400px|thumb|CEB Press (aka "The Liberator"). See [[CEB_Press_6#Instructional_Files]] for detailed pictures of the latest machine build (v6), and for an exact picture of v6. Version shown is v3.]] | |||

[[File:Liberator_bricks.JPG|right|400px|thumb|Bricks pressed on [[The Liberator]]]] | |||

The Liberator is OSE's automatic, high throughput Compressed Earth Brick Press. It is named The Liberator because it is intended to free people from the single highest cost of living - housing. See [[Cost of Living]]. | |||

#The | The CEB is at product release status and is being actively manufactured at Factor e Farm. The presses was used heavily as a part of the [[Factor e Farm Infrastructure Buildout 2011]]. Builds using the OSE CEB ress continued with the [[Microhouse 1]], [[Microhouse 2]], [[Microhouse 3]], and [[MicroHouse 4]] built in 2014 - [http://www.prweb.com/releases/2015/01/prweb12440135.htm]. We have also built a utility room brick floor and an 8' wall section out of CEBs in the 2016 build of the [[Seed Eco-Home]]. | ||

In 2020, we did a [[CEB Microhouse Build in Belize]]. | |||

The bill of materials cost of the current, fully-automated machine is about $5000 US. See [[CEB Press#BOM]]. | |||

The machine can also be made as a manually-controlled version with hydraulic valves. Other options are: | |||

*small or large hopper | |||

*with or without hopper shaker | |||

*automatic controller at 6-10 bricks per minute, depending on power unit | |||

'''We are currently selling the full machine without power unit for $10k FOB Kansas City, lead time 2 months. Email info at opensourceecology dot org.''' | |||

*Price is FOB Kansas City, Missouri, USA, for a fully assembled machine, with quick couplers, ready to be plugged in to a power source. Price for other packing/crating options is extra. | |||

*Delivery time: machines are produced during scheduled production runs, with 8 weeks lead time from submission of payment. | |||

*Buyer is encouaraged to attend the build event - to learn how the machine is designed, built, and therefore, to learn about repair and modification. Basic instruction on using FreeCAD will be provided for viewing the CAD file. An operating and maintenance manual will be provided to the client. The buyer is encouraged to brind additional people to the build event to learn about the machine. | |||

A tractor loader is used to provide approximately 2 cubic yards of soil per hour at at 6 block per minute pressing rate. A tractor loader is needed to keep up with the machine throughput. Approximately 3 people are required to keep up with the machine for stacking the block upon pallets. Approximately 30 people would be required to load the machine manually with shovels and buckets if no tractor loader were available. At the minimum, 4 people (1 tractor operator, 3 stackers) are required to produce palletized block on an all-day basis. | |||

==Specifications of the Standard Model== | |||

*Block is plain block, not interlocking. Please see discussion on [[Interlocking_bricks]] | |||

*Version 17.08 is our most current model. See [[CEB Press Genealogy]] for past versions. | |||

*Open source hardware, controller, and software ([[CC-BY-SA 4.0]], [[GPLv3]]) | |||

*Controller is fully automated for hands-off operation | |||

*Does NOT come with a power source - it is powered by a hydraulic power source, such as by our [[Power Cube]] or a tractor hydraulic take-off. | |||

*Full size bricks are 4"x6"x12", plain flat-faced bricks | |||

*Brick height is adjustable from 2"-4" | |||

*Brick dimensional variations: +/- 1/16". This assumes uniform soil. Soil uniformity will determine height uniformity of brick. | |||

*The standard model guarantees 6 full-sized bricks per minute at 12.5 gallon per minute hydraulic flow. See [[Brick Pressing Calculations]]. Brick pressing rate will increase with a higher hydraulic flow, up to the maximum rated flow of the hydraulic solenoid. Hydraulic solenoid valve is rated for a maximum of 10 gpm fluid flow at 3000PSI. | |||

*Cost of production for actual block ranges from 5 cents to 40 cents per block - depending on amount of cement used for stabilization (0-10%) and cost of labor (free to $25/hr). See [[Cost_of_CEB_Block]] | |||

*Fuel consumption with [[Power Cube]] running at 12.5 gpm fluid flow - about 1 gallon per hour | |||

*System hydraulic pressure - 2400 psi | |||

*Comes with hydraulic quick couplers ready to be connected to a power source | |||

*Weight - 1700 lb | |||

*Moving: brick press is moved with forks. Footprint (with legs in the inner position) allows machine to be placed in the bed of a 3/4 ton pickup. It has adjustable legs for uneven terrain. Machine can be moved around on a trailer (not included) | |||

*Material cost: $3000-$6500 depending on suppliers; manual machine (without hydraulic solenoid, machine costs $1000 less in materials. Production cost for a full kit: US$5000 above the bill of materials/supplies/consumables cost, paid by the buyer. Production currently occurs in [[Extreme Manufacturing]] Workshops - where the buyer is invited to the build so they understand how the machine is built - and is part of the buyer's Lifetime DIY Warranty. This warranty means that the user can maintain the machine for decades because they know how the machine is built, how it works, and how to source parts for the machine from local and online sources. This means that this is not a consumer machine, but a prosumer machine. | |||

*3'x6' grate for loading the machine with a tractor. Includes soil deflectors | |||

=Additional Power= | |||

The machine can be used to produce up to 10 blocks per minute with a larger power source. A larger secondary hydraulic cylinder must be used in that case. See [[CEB Press Log]] for developments. | |||

=BOM= | |||

See build BOM from 2017 at [[CEB_Press_v17.08#BOM]] | |||

=Versions= | |||

{{Hint|'''For full project version history, see [[CEB Press Genealogy]] and [[CEB Press Controller Genealogy]]'''}} | |||

=Details= | |||

The CEB Press takes earth/dirt/soil and compresses it tightly to make solid blocks useful for building. Compressed earth blocks have many advantages as a building material: by making the building materials from the readily available dirt on the building site, they eliminate the need to transport bricks from elsewhere, reducing financial cost and environmental impact. Compressed earth blocks are very strong and insulate well against both heat and sound, making for very energy-efficient building (especially combined with the energy savings from not needing to transport them from offsite). Best of all, the material they use is already on-site and does not need to be purchased -- quite literally, dirt-cheap! See the wiki page on [[Compressed Earth Blocks]] and the [[:Category:CEB|CEB category]] for more details on building using CEBs. | |||

The Liberator has been fully designed and tested by the [[Open Source Ecology]] team. Because the Liberator is an open source technology, you can freely download instructions to build your own from materials you can obtain yourself, or contact ''opensourceecology[at]gmail[dot]com'' to buy a kit or a finished machine. | |||

Building a machine yourself might seem intimidating, but every step of the process is fully documented and the OSE community is available on our [http://forum.opensourceecology.org/ discussion forums] if you need help, advice, or a little hand-holding. | |||

Using the CEB Press, two people can build a 6 foot high (1.83m) round wall, 20 feet (6.1m) in diameter, 1 foot (30cm) thick, in one 8 hour day, though construction time will vary somewhat depending on preparation time, what equipment is available (tractor to prepare the ground and move the blocks where they need to go), the quality of the soil, and other factors. The bigger the block size, the faster a wall can be erected, but at the cost of heavier blocks that are more of a strain to work with. Blocks from ''The Liberator'' average 25 pounds (11.3kg). | |||

See [[CEB Design]] for more information. | |||

=Product Ecology= | |||

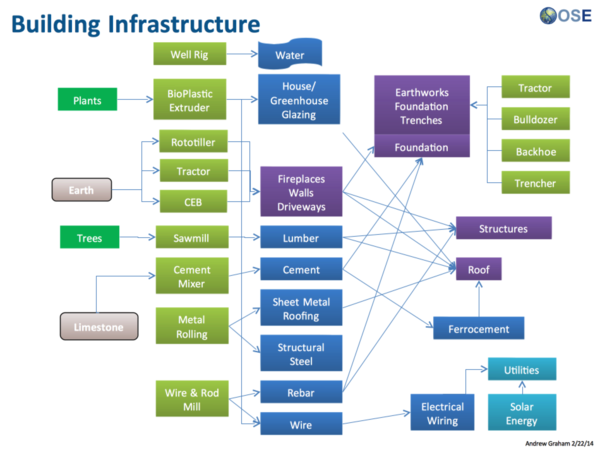

[[Image:4b-Constructioneco.png|thumb|600px|center|Construction [[Product Ecology]]]] | |||

'''From''' | |||

*{{Furnace}} | |||

*{{Welder}} | |||

*{{Torch Table}} | |||

*{{Ironworker}} | |||

'''Uses''' | |||

*{{PowerCube}} | |||

*{{Rototiller}} | |||

*{{Tractor}} | |||

*[[Earth]] | |||

'''Creates''' | |||

*[[CEB Bricks]] | |||

'''Enables''' | |||

*[[Workshop]] | |||

*[[Greenhouse]] | |||

*[[HabLab]] | |||

=See Also= | |||

*[[CEB Press Genealogy]] | |||

*[[Brick Pressing Calculations]]. | |||

*[http://collections.infocollections.org/ukedu/uk/d/Jh2380e/4.3.1.html Soil Testing] | |||

*[http://collections.infocollections.org/ukedu/uk/d/Jh2380e/4.3.2.html more Soil Testing] | |||

*[[CEB Design]] | |||

*[[Compressed Earth Blocks]] | |||

*[[Cinva Ram]] | |||

*[[CEB_FAQ]] | |||

*[[CEB Press/Rollers]] | |||

*[[CEB Press/ModularRollers]] | |||

*[[Hablab]] | |||

*[[Metric CEB Press]] | |||

*[[CEB Press/Field Testing 2011|Field Testing 2011]] | |||

*[[CEB Press/Videos]] | |||

{{GVCS Footer}} | |||

[[Category:CEB Press]] [[Category:GVCS]] | |||

Latest revision as of 01:46, 30 April 2021

Link to CEB Press Build June 2015

The CEB Story 2012. from Open Source Ecology on Vimeo.

| CEB Press | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

The Liberator is OSE's automatic, high throughput Compressed Earth Brick Press. It is named The Liberator because it is intended to free people from the single highest cost of living - housing. See Cost of Living.

The CEB is at product release status and is being actively manufactured at Factor e Farm. The presses was used heavily as a part of the Factor e Farm Infrastructure Buildout 2011. Builds using the OSE CEB ress continued with the Microhouse 1, Microhouse 2, Microhouse 3, and MicroHouse 4 built in 2014 - [1]. We have also built a utility room brick floor and an 8' wall section out of CEBs in the 2016 build of the Seed Eco-Home.

In 2020, we did a CEB Microhouse Build in Belize.

The bill of materials cost of the current, fully-automated machine is about $5000 US. See CEB Press#BOM.

The machine can also be made as a manually-controlled version with hydraulic valves. Other options are:

- small or large hopper

- with or without hopper shaker

- automatic controller at 6-10 bricks per minute, depending on power unit

We are currently selling the full machine without power unit for $10k FOB Kansas City, lead time 2 months. Email info at opensourceecology dot org.

- Price is FOB Kansas City, Missouri, USA, for a fully assembled machine, with quick couplers, ready to be plugged in to a power source. Price for other packing/crating options is extra.

- Delivery time: machines are produced during scheduled production runs, with 8 weeks lead time from submission of payment.

- Buyer is encouaraged to attend the build event - to learn how the machine is designed, built, and therefore, to learn about repair and modification. Basic instruction on using FreeCAD will be provided for viewing the CAD file. An operating and maintenance manual will be provided to the client. The buyer is encouraged to brind additional people to the build event to learn about the machine.

A tractor loader is used to provide approximately 2 cubic yards of soil per hour at at 6 block per minute pressing rate. A tractor loader is needed to keep up with the machine throughput. Approximately 3 people are required to keep up with the machine for stacking the block upon pallets. Approximately 30 people would be required to load the machine manually with shovels and buckets if no tractor loader were available. At the minimum, 4 people (1 tractor operator, 3 stackers) are required to produce palletized block on an all-day basis.

Specifications of the Standard Model

- Block is plain block, not interlocking. Please see discussion on Interlocking_bricks

- Version 17.08 is our most current model. See CEB Press Genealogy for past versions.

- Open source hardware, controller, and software (CC-BY-SA 4.0, GPLv3)

- Controller is fully automated for hands-off operation

- Does NOT come with a power source - it is powered by a hydraulic power source, such as by our Power Cube or a tractor hydraulic take-off.

- Full size bricks are 4"x6"x12", plain flat-faced bricks

- Brick height is adjustable from 2"-4"

- Brick dimensional variations: +/- 1/16". This assumes uniform soil. Soil uniformity will determine height uniformity of brick.

- The standard model guarantees 6 full-sized bricks per minute at 12.5 gallon per minute hydraulic flow. See Brick Pressing Calculations. Brick pressing rate will increase with a higher hydraulic flow, up to the maximum rated flow of the hydraulic solenoid. Hydraulic solenoid valve is rated for a maximum of 10 gpm fluid flow at 3000PSI.

- Cost of production for actual block ranges from 5 cents to 40 cents per block - depending on amount of cement used for stabilization (0-10%) and cost of labor (free to $25/hr). See Cost_of_CEB_Block

- Fuel consumption with Power Cube running at 12.5 gpm fluid flow - about 1 gallon per hour

- System hydraulic pressure - 2400 psi

- Comes with hydraulic quick couplers ready to be connected to a power source

- Weight - 1700 lb

- Moving: brick press is moved with forks. Footprint (with legs in the inner position) allows machine to be placed in the bed of a 3/4 ton pickup. It has adjustable legs for uneven terrain. Machine can be moved around on a trailer (not included)

- Material cost: $3000-$6500 depending on suppliers; manual machine (without hydraulic solenoid, machine costs $1000 less in materials. Production cost for a full kit: US$5000 above the bill of materials/supplies/consumables cost, paid by the buyer. Production currently occurs in Extreme Manufacturing Workshops - where the buyer is invited to the build so they understand how the machine is built - and is part of the buyer's Lifetime DIY Warranty. This warranty means that the user can maintain the machine for decades because they know how the machine is built, how it works, and how to source parts for the machine from local and online sources. This means that this is not a consumer machine, but a prosumer machine.

- 3'x6' grate for loading the machine with a tractor. Includes soil deflectors

Additional Power

The machine can be used to produce up to 10 blocks per minute with a larger power source. A larger secondary hydraulic cylinder must be used in that case. See CEB Press Log for developments.

BOM

See build BOM from 2017 at CEB_Press_v17.08#BOM

Versions

![]() Hint: For full project version history, see CEB Press Genealogy and CEB Press Controller Genealogy

Hint: For full project version history, see CEB Press Genealogy and CEB Press Controller Genealogy

Details

The CEB Press takes earth/dirt/soil and compresses it tightly to make solid blocks useful for building. Compressed earth blocks have many advantages as a building material: by making the building materials from the readily available dirt on the building site, they eliminate the need to transport bricks from elsewhere, reducing financial cost and environmental impact. Compressed earth blocks are very strong and insulate well against both heat and sound, making for very energy-efficient building (especially combined with the energy savings from not needing to transport them from offsite). Best of all, the material they use is already on-site and does not need to be purchased -- quite literally, dirt-cheap! See the wiki page on Compressed Earth Blocks and the CEB category for more details on building using CEBs.

The Liberator has been fully designed and tested by the Open Source Ecology team. Because the Liberator is an open source technology, you can freely download instructions to build your own from materials you can obtain yourself, or contact opensourceecology[at]gmail[dot]com to buy a kit or a finished machine.

Building a machine yourself might seem intimidating, but every step of the process is fully documented and the OSE community is available on our discussion forums if you need help, advice, or a little hand-holding.

Using the CEB Press, two people can build a 6 foot high (1.83m) round wall, 20 feet (6.1m) in diameter, 1 foot (30cm) thick, in one 8 hour day, though construction time will vary somewhat depending on preparation time, what equipment is available (tractor to prepare the ground and move the blocks where they need to go), the quality of the soil, and other factors. The bigger the block size, the faster a wall can be erected, but at the cost of heavier blocks that are more of a strain to work with. Blocks from The Liberator average 25 pounds (11.3kg).

See CEB Design for more information.

Product Ecology

From

Uses

Creates

Enables

See Also

- CEB Press Genealogy

- Brick Pressing Calculations.

- Soil Testing

- more Soil Testing

- CEB Design

- Compressed Earth Blocks

- Cinva Ram

- CEB_FAQ

- CEB Press/Rollers

- CEB Press/ModularRollers

- Hablab

- Metric CEB Press

- Field Testing 2011

- CEB Press/Videos