Plasma Cutter/Research Development: Difference between revisions

Jump to navigation

Jump to search

| Line 2: | Line 2: | ||

=Performance= | =Performance= | ||

*Pierces up to 1.5" metal - [https://www.ezcutcnc.com/maximum-material-thickness-plasma-cutter-can-handle/] | *Pierces up to 1.5" metal - [https://www.ezcutcnc.com/maximum-material-thickness-plasma-cutter-can-handle/] | ||

*Cuts up to 6" - [https://www.ezcutcnc.com/maximum-material-thickness-plasma-cutter-can-handle/] | |||

*Kerf wider than autogenous cutting (oxyfuel) | |||

==Research== | ==Research== | ||

Latest revision as of 12:43, 7 April 2018

| Plasma Cutter | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Performance

Research

Lawrence Kincheloe used a commercial plasma cutter with his Torch Table Build as part of his project based visits to Factor e Farm.

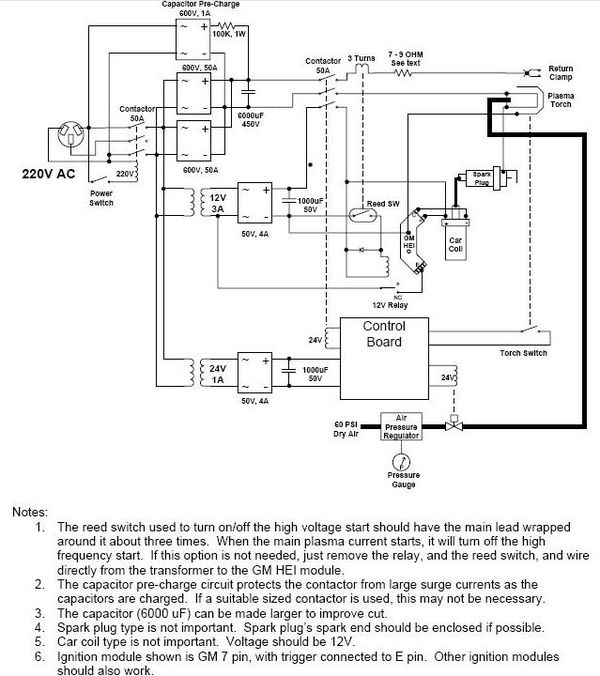

Design

- Powered by Universal Power Supply

- Open Source gun

- Modular: power supply, gas feed, control, and gun are separate

- Stackable power unit as in this

- Arduino or DIY microprocessor-controlled

See Also