Power Cube/Research Development: Difference between revisions

Jump to navigation

Jump to search

Tom Griffing (talk | contribs) No edit summary |

|||

| (44 intermediate revisions by 9 users not shown) | |||

| Line 1: | Line 1: | ||

{{GVCS Header}} | |||

=Overview= | |||

The powercube has undergone a number of revisions and modifications. With each prototype, different aspects of the design were refined and improved in pursuit of meeting [[OSE Specifications]]. | |||

== | =Prototypes= | ||

==Power Cube I== | |||

[[Image:Microtrac engineback1.jpg|400px]] | |||

==Power Cube II== | |||

[[File:Powercube-ii-front.jpg|400px]] | |||

<html> | |||

<a href="http://vimeo.com/15892882">How to build an OSE Power Cube (full length)</a> from <a href="http://vimeo.com/user3935797">Will OSE</a> on <a href="http://vimeo.com">Vimeo</a>: | |||

<p><iframe src="https://player.vimeo.com/video/15892882?title=0&byline=0&portrait=0" width="400" height="300" frameborder="0"></iframe> | |||

</html> | |||

==Power Cube III== | |||

[[Power Cube III]] | |||

==Power Cube IV== | |||

This is the latest Power Cube, as of September 2011. | |||

<br /> | |||

Please visit the links at the top of this page for the latest Bill Of Materials (BOM) and Manufacturing Instructions. | |||

==Power Cube V== | |||

[[Power Cube V]] | |||

==Power Cube VI== | |||

[[Power Cube VI]] (preview) | |||

[[Power Cube 6]] (more complete documentation) | |||

==Power Cube (n)== | |||

* visual indicator of fluid level would be helpful. | |||

** Perhaps 90* fittings could be inserted into the vertical frame-tank members and a clear tube could be run between them. | |||

* [[Power_Cube_VI_Review]] | |||

** move the muffler away from the driver. | |||

** re-position hoses to prevent accidental collision damage. | |||

** lower the temperature switch setting. | |||

** remote throttle/keyswitch? | |||

* address engine oil drain? | |||

** http://opensourceecology.org/wiki/Power_Cube_6/User%27s_Manual | |||

* double chain coupler? | |||

** http://opensourceecology.org/wiki/Power_Cube_6/Manufacturing_Instructions | |||

==Power Cube E== | |||

Electric power cube | |||

: | https://www.surpluscenter.com/item.asp?item=10-2661 | ||

*254T frame | |||

*Shaft 1-5/8" dia. x 4.2" w/3/8" keyway | |||

*Size 18" x 13" x 12" | |||

[http://www.engineeringtoolbox.com/nema-electrical-motor-frame-dimensions-d_1504.html frame dimensions] | |||

==Power Cube WS== | |||

power cube with 50HP to be mounted in wikispeed car frame. utilizing a refurbished VW bug engine. | |||

[[Power Cube WS]] | |||

=Industry Standards= | |||

=Research= | |||

[[ Hydraulic Hose Sizing ]] | |||

[[ Hydraulic Connectors ]] | |||

[[ Cooling and Heating ]] | |||

[[ Fuel Tank ]] | |||

[[ Shaft Coupling ]] | |||

[[Power Cube/Controller]] | |||

[http://www.machinerylubrication.com/Read/28430/hydraulic-pump-motors-maintenance pump efficiency] | |||

=Development= | |||

[[Modular power cubes]] concept development | |||

{{GVCS Footer}} | |||

Latest revision as of 21:45, 5 February 2014

| Power Cube | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

The powercube has undergone a number of revisions and modifications. With each prototype, different aspects of the design were refined and improved in pursuit of meeting OSE Specifications.

Prototypes

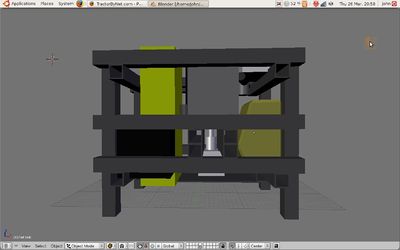

Power Cube I

Power Cube II

How to build an OSE Power Cube (full length) from Will OSE on Vimeo:

Power Cube III

Power Cube IV

This is the latest Power Cube, as of September 2011.

Please visit the links at the top of this page for the latest Bill Of Materials (BOM) and Manufacturing Instructions.

Power Cube V

Power Cube VI

Power Cube VI (preview)

Power Cube 6 (more complete documentation)

Power Cube (n)

- visual indicator of fluid level would be helpful.

- Perhaps 90* fittings could be inserted into the vertical frame-tank members and a clear tube could be run between them.

- Power_Cube_VI_Review

- move the muffler away from the driver.

- re-position hoses to prevent accidental collision damage.

- lower the temperature switch setting.

- remote throttle/keyswitch?

- address engine oil drain?

- double chain coupler?

Power Cube E

Electric power cube

https://www.surpluscenter.com/item.asp?item=10-2661

- 254T frame

- Shaft 1-5/8" dia. x 4.2" w/3/8" keyway

- Size 18" x 13" x 12"

Power Cube WS

power cube with 50HP to be mounted in wikispeed car frame. utilizing a refurbished VW bug engine.

Industry Standards

Research

Development

Modular power cubes concept development