Pelletizer/Research Development: Difference between revisions

Jump to navigation

Jump to search

(Added some more information) |

(Added some more information) |

||

| Line 44: | Line 44: | ||

<iframe width="320" height="190" src="https://www.youtube.com/embed//OxChBQf-PLI" frameborder="0" allowfullscreen></iframe> | <iframe width="320" height="190" src="https://www.youtube.com/embed//OxChBQf-PLI" frameborder="0" allowfullscreen></iframe> | ||

</html> | </html> | ||

=Existing Open Source Designs= | |||

==Precious Plastic== | |||

*Odd idea, but could the [[Precious Plastic Extrusion Machine]] , or especially the pro version, be modified to handle non-plastic pellet making? | |||

*Main concern is dust getting where it shouldn't, but molten plastic is viscous, and tends to leak, so perhaps it will be fine? | |||

*Also are the required pressures reached? | |||

*Also a powder hopper, a stepper motor, and the cutting disk seem like the only additions needed | |||

=See Also= | =See Also= | ||

Revision as of 18:13, 8 April 2020

| Pelletizer | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Basics

- This page aims to organise and conduct research on the Pelletizer.

Main Types of Pelletizers

Screw Based

- Similar to a filament extruder, but with a rotating "cutter" on one end

- Changing the speed of the cutter wheel changes the pellet length

- Due to being able to seal the tube, and still run the screw, can higher densities be reached due to the increased pressure? Needs More Research

- These have less throughput, so may not be the best option for large scale use, but better for home use perhaps

Die Based

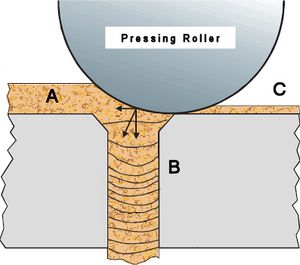

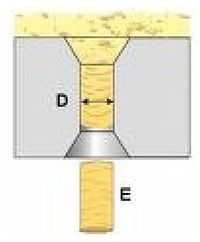

- Typically use a roller, and a sort of mesh/honecomb with the holes being the shape and dimention of the pellets

- Powder is added to the top and is pushed through the mesh making pellets

- VERY high throughput

- Often unpressed powder mixed in output, so more post processing is needed such as a shaker grate

- May have less pressure and thus lower density?

- Also can pellet length be varied (perhaps swapping screen for one with longer "tubes"

- OR some sort of dual mesh device with rotating wheels with holes, so it can be "sealed" like the screw extruder?

Walkthrough

Sawdust from Sawmill

Existing Open Source Designs

Precious Plastic

- Odd idea, but could the Precious Plastic Extrusion Machine , or especially the pro version, be modified to handle non-plastic pellet making?

- Main concern is dust getting where it shouldn't, but molten plastic is viscous, and tends to leak, so perhaps it will be fine?

- Also are the required pressures reached?

- Also a powder hopper, a stepper motor, and the cutting disk seem like the only additions needed

See Also

- Nick on the Pelletizer

- Pelletizer die and roller quote - Quote

- Kiln

Useful Links

- Chinese supplier of pelletizers

- Pellet Burners

- Images of Rollers and Dies

- Penn State on manufacturing fuel pellets