LifeTrac III/Research Development: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

{{ | {{GVCS Header}} | ||

=Research= | =Research= | ||

| Line 165: | Line 163: | ||

=See Also= | =See Also= | ||

[[OSTrac]] | [[OSTrac]] | ||

{{GVCS Footer}} | |||

Revision as of 00:30, 6 September 2011

| LifeTrac III | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Research

Goals

- Lifetime design

- Scalable

- Modular

- Easy to maintain

General design goals

- Skid loader concept

- Articulated steering

- 4 wheel drive

- 2 wheel drive for doubled speed

- Front-end loader

- Backhoe attachment available

- Well-drilling attachment available

- CEB attachment available

- Hybrid between a skid loader, agricultural tractor, and construction tractor

Features

It has a number of features that set it apart from skid loaders and make these vehicles suitable for agriculture. The main features for agriculture are a 3-point hitch, power takeoff, and high-flow hydraulic takeoff. These features make the LifeTrac capable of using any agricultural implements.

LifeTrac is also designed with a winch, and is designed to be equipped with well-drilling equipment with 10-foot drilling pipe sections.

As such, the design is one of highest utility and versatility, combining the power of skid loaders with agricultural tractors and construction tractors. A Compressed Earth Block press CEB Press is designed for use as an implement with LifeTrac, and a backhoe as well.

The unique feature is the modularity and design for dis-assembly. Priority one is lifetime design, where any problem can be troubleshooted and fixed readily. Bye-bye to $1-2,000 transmission jobs at the shop. No transmission is required - it's built-in to the hydraulic drive.

Components are designed to be standard steel as much as possible. The goal is to have the user-owner fully capable of maintenance. By design, no issue in LifeTrac should be more expensive than $250 to fix. Standard steel components (sheet, tubing, shaft, etc.) is used, with no forming or machining outside of minor welding and lathing, for repair and construction of OSTrac.

Evolution

- Flash-steam bladeless turbine drive being explored

- Flash-steam electric hybrid drive being developed

Wanted: Brief description about the highest version of the LifeTrac

Theory

Wanted: Brief paragraph regarding the reasoning behind adding this tool to the GVCS

Relevant Links

Wanted: Sources for information regarding relevant technology

Conceptual Notes

Wanted: Ifs, ands and buts.

Development

For us at Factor e Farm, LifeTrac will be the backbone of our agricultural, agroforestry, and land stewardship operations. It will also be used in construction, power generation, and possibly other workshop tools. Interestingly, hybrid hydraulic drive also applies to cars - here's an example [1]. The identical hydraulic design, minus agricultural implement features - can be used with a car - simply by using faster, lower-torque wheel motors.

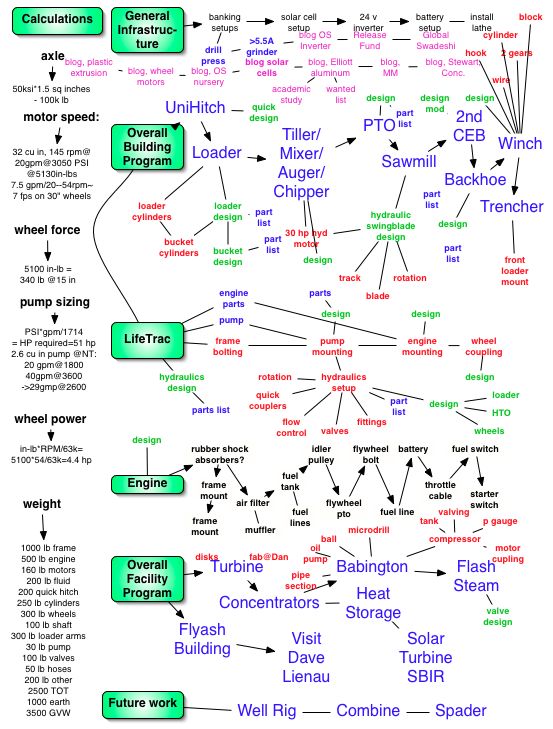

The basic drive is all hydraulic, and all implements are run hydraulically as well. Three hydraulic motors - PTO motor, high torque motor, and winch motor are used for accessory power applications. These can drive the following devices which we are also building contemporaneously:

- Tilt-blade sawmill

- Rototiller

- Post-hole digger/tree planter

- Mixer

- Winch

- Well-drilling rig (future work)

Other implements that we are preparing are:

- CEB Press

- Backhoe

- Trencher

The unique feature is that the motors can be mounted on the front-end laoder quick-connect plate - which serves, in effect, as an implement attachment mechanism that is much more versatile than a tractor 3 point hitch. All implements may be mounted on the quick-connect

As of 5.24.08, the current working program surrounding LifeTrac is:

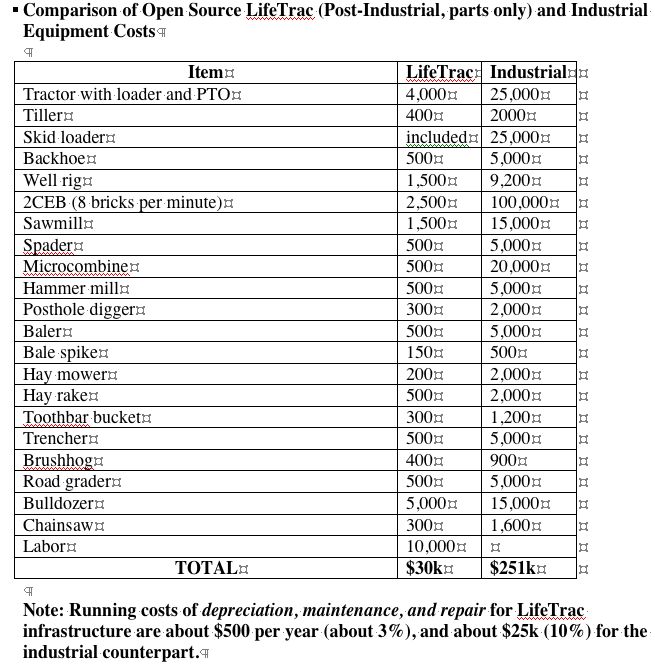

Cost Comparisons to Industrial Counterparts

- NOTE: Industrial prices are taken largely from Northern Tool catologue - [2] - your local, global supply chain.

- Commercial hydraulic rotary well drilling rig quote - [3]

- Note: Tractor and Bulldozer add up to $9k, for an infrastructure that shares wheel motors, controls, and Power Cubes. Power Cubes are $1750 each for 27 hp using off-shelf components. For about 100 hp of drive, this is $7k.

- Note: Since Power Cubes are not included here, the real cost of the package should be closer to $40k for the GVCS implementation prior to the ability to melt steel into virgin metal. This ability, combined with advanced CNC machining, will bring the cost down to about $5000 for 50,000 lbs of steel obtained from scrap sources.

- Note: Each device takes on average 1 week to fabricate after optimization to digital fabrication. This implies a total labor time of about 20 weeks for the devices above, or only $15/hour at the labor cost given. This may be acceptable for DIY value, but is a low rate for market production.

Maintenance

- Yearly maintenance costs designed to be no more than $100 with heavy duty usage

- What are the key points in a maintenance check?

- What are the skill sets required to perform a systems check accurately?

Bill of Materials for Industrial Counterparts

- One tire and rim - a flat proof one - costs $500 for skid loaders - [4]. Compare to $5 used truck tires with $35 for open source chains - under $50 for a tire. The latter affords the same traction, at 10-100 times less cost, depending if you count the chains or not.

- Which is more cost effective over a lifetime?

Design

The concept was inspired initially by CADTrac, a set of plans that you can buy:

But it is redesigned thoroughly by enlarging the size and making construction simpler, to fulfill OSE Specifications for Post-Scarcity Economics.

- Requirements

- Speed

- Throughput

- Weight

- Size Constraints

- Feed stock

- Design Description

- Calculations

- Drawings and Diagrams

- Concept and Alternatives

- Full Design Views

- Cut-away Views

- Exploded Parts View

- 3D Renders

- Decisions

- Project Team

Industry Standards

| Industry Standard | LifeTrac |

|---|

Funding

Wanted: List of expenses for prototyping and documenting LifeTrac

Peer Reviews

Wanted: Peer reviews from the scientific community regarding the R&D of LifeTrac

Experiments and Prototypes

Wanted: Empirical data on performance

Experimental Results

Prototype Notes, Observations, etc.

Failure Mode Analysis

Testing Results

Recommendations for Improvement

See Also