Power Cube/Research Development: Difference between revisions

Jump to navigation

Jump to search

Matt Maier (talk | contribs) No edit summary |

Matt Maier (talk | contribs) |

||

| Line 22: | Line 22: | ||

Please visit the links at the top of this page for the latest Bill Of Materials (BOM) and Manufacturing Instructions. | Please visit the links at the top of this page for the latest Bill Of Materials (BOM) and Manufacturing Instructions. | ||

==Power Cube ( | ==Power Cube (n)== | ||

A visual indicator of fluid level would be helpful. Perhaps 90* fittings could be inserted into the vertical frame-tank members and a clear tube could be run between them. The gauges could be put on one of the inside surfaces and protected with some plate steel on each side like how the fill-caps are protected. | A visual indicator of fluid level would be helpful. Perhaps 90* fittings could be inserted into the vertical frame-tank members and a clear tube could be run between them. The gauges could be put on one of the inside surfaces and protected with some plate steel on each side like how the fill-caps are protected. | ||

Revision as of 19:43, 17 December 2011

| Power Cube | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

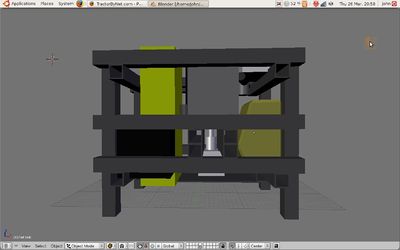

The powercube has undergone a number of revisions and modifications. With each prototype, different aspects of the design were refined and improved in pursuit of meeting OSE Specifications.

Prototypes

Power Cube I

Power Cube II

How to build an OSE Power Cube (full length) from Will OSE on Vimeo.

Power Cube III

Power Cube IV

This is the latest Power Cube, as of September 2011.

Please visit the links at the top of this page for the latest Bill Of Materials (BOM) and Manufacturing Instructions.

Power Cube (n)

A visual indicator of fluid level would be helpful. Perhaps 90* fittings could be inserted into the vertical frame-tank members and a clear tube could be run between them. The gauges could be put on one of the inside surfaces and protected with some plate steel on each side like how the fill-caps are protected.

Research