Car/Research Development

| Car | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

News

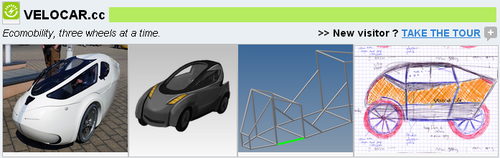

The OSE Micro Car is Vélocar. Please join us on velocar.cc for research development.

Actual step in OSE organisation : Universal Mobility Construction Set

Joe Justice recruited as collaborator on 2/20/2012.

See Status Brief for update

Overview

Car Research

Car Research

Concept

4" Tube Frame Concept

The Tractor uses 4" tubes, so it makes sense to try to reuse that approach for the rest of the first-generation machines. This is a concept for the open source car that uses 4" tubes arranged in triangles to form a sort of ladder frame that additional parts like wheels and power cubes can be mounted to.

Considerations

- Requirements

- Speed

- Throughput

- Weight

- Size Constraints

- Feed stock

- Design Description

- Calculations

- Drawings and Diagrams

- Concept and Alternatives

- Full Design Views

- Cut-away Views

- Exploded Parts

- 3D Renders

- Decisions

- Project Team

Design

Car/Research Development/Calculations

The basic requirements for the OS Car are: Two passenger capacity, Ultra-high fuel economy (50+ MPG, city, 100+ MPG, highway), Ultra-long range (1000+ miles), Low Cost (less than $12,000), Ease of Construction (1000 hours of construction time. Can be constructed by one person in 1000 hours with a vertical mill, band saw, disc sander, grinding wheel, air compressor, welder)

Given these requirements the basic attributes chosen for the OS Car are:

- Reverse Trike Layout

The reverse trike layout was chosen because it allows for side by side seating, an aerodynamic rain drop shaped body, and safe handling. A two-wheeled vehicle with tandem seats resembling a motorcycle would have less frontal area and probably less wind drag, but would simply not be practical to drive. A four-wheeled vehicle could be made with a rain drop shaped body, but would have extra drag from the two rear wheels which would protrude from the body. The reverse trike design may seem novel, but has been used successfully for over 100 years in cars from the Egg to the Aptera. Other benefits to the reverse trike layout are lower weight and cost due to the obviation of one wheel and a differential. NOT.

- Hybrid Hydraulic Powertrain

A hybrid powertrain is a requirement for achieving high fuel efficiency in city driving in order to: 1. Exploit the low brake specific fuel consumption (BSFC) of a very small displacement engine which cannot create enough power by itself to provide sufficient acceleration of a vehicle. 2. Allow for regenerative braking where kinetic energy of the vehicle is recaptured and stored. Hybrid electric powertrains are most popular in hybrid vehicles produced by the major OEMs, but using a such a powertrain in the OS Car would require either very expensive lithium-ion batteries, or very heavy lead-acid batteries. A hybrid hydraulic powertrain would not require any batteries for energy storage and would instead use a relatively lightweight and low cost accumulator.

off-the-shelf hydraulic transmission

commerical hybrid hydraulic trucks

UPS uses hybrid hydraulics...also Tuan Nguyen is an idiot.

good analysis of hydraulic hybrid benefits

a description of the active hydraulic suspension on the Infinity Q45a

problems with hydropneumatic suspension design on Lexus LX 470

- Tubular Steel Space Frame

A tubular steel space frame design was chosen for the space frame because it will be lightweight, stiff, strong, relatively inexpensive, and easy to construct. Although aluminum tubing would allow for a lighter design, its cost would be unacceptably high. A composite monocoque is and alternative to a space frame design, but a monocoque would require costly molds, and would require a large amount of time and a fair amount of skill to construct.

Research

- [1]

- River Simple Urban Car

- UEV Zero - a brazilian project

- OSCar Project - German project]

- OSCar UK - UK project

- OSCar - Netherlands project

- The Rally Fighter - a completed open-source car

- HyrBan, an open-source, hydrogen-powered car. In prototype phase.

- Africar

- Smart Roadster

- Book; build your own sports car for $500

- assemble your own car

- Ron Champion's Locost self-sourced kit car

- hydraulic innovations forum

- forum on hydraulic drivetrains

- Tri-Magnum 3-wheel kit car

- T-Rex

- Volkswagen GX-3

- Zap Alias

- Elio

- Aptera 2e

- BMW Isetta

- Myers Motors

- 3 wheeled car on wikipedia

- Reverse Trike group page

See Also

- Car Concept Design

- Electrilite

- NiFe Vehicles

- Truck

- Hybrid Hydraulic System

- Don Banky's hydraulic car

- Vincent Carman's hydraulic car

- Team Wikispeed on Top Speed and Seattle Met

- osvehicle