Bioplastic Extruder/Research Development

| Bioplastic Extruder | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

Bioplastics

Cellophane is reformulated cellulose (wood), produced via an acid and base dunk of sawdust. This may be used in glazing. Car bodies may be made; the original car bodies for Ford were soybean-derived bioplastics.

Polylactic acid (PLA) can be made by fermenting starch or with hay in silage.

Mycelium can be placed in a mold with grain husks, wheat straw or any of a wide variety of other biomass (with different end product results) and be made into a variety of useful products, including a durable closed cell foam substitute.

Links

- plastics extrusion

- Wikipedia: Plastics Extrusion

- Wikipedia: Thermoforming

- Wikipedia: Vacuum Forming

- Wikipedia: Injection Molding

- Strictly Extrusion

- Society of Plastics Engineers

- SPE Online Technical Library

Open Source Extruders

- Precious Plastic - prototype filament maker. Note that the hopper feed mechanism appears to be robust, so that regrind can be used readily.

Plastic Lumber Version Of the Precious Plastic Design

- Compare to Lyman Filament Extruder, which works well with pellets, but it is not clear if it would work robustly with regrind.

Co-Extrusion

Do different plastics mix well for making 3D printing filament? Yes, there are good combinations shown at [1]

- Good examples: PC/PET, ABS/PVC. For PC/PET - that could be a good combination mixing best properties of both.

See Also

- Waste Plastic Extruder: Literature Review

- Bioplastics

- Plastic Extrusion & Molding

- Upper Austria Green Biorefinery

- Polyethylene from Ethanol

Industry Standards

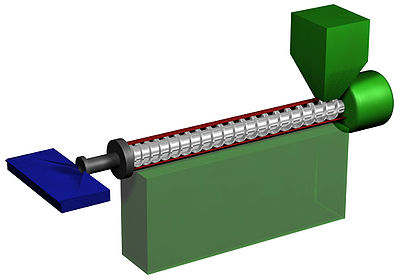

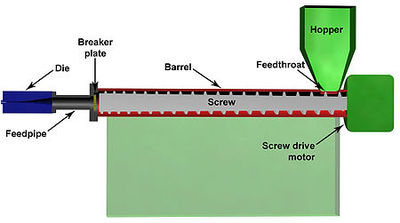

Horsepower, heating power, and screw size will determine throughput.

- Extruders on Ebay - $3k up - 30 hp motor, 1.5 - [2]

- Greiner-GCE-30-F-CO-Extruder-Plastics-Processing-Machine-30mm-1-1811-034-Screw - $4500 on Ebay - info PDF - [greiner-extrusion-group.com/files/greiner/downloads/Greiner%20Extrusion%20Group_Fact%20Sheet%20Co-Extruder_GCE_DE_EN.pdf]. Smallest one is 10kW - 5kW motor, and 2 zones of barrel heating at 1 kW each, and 2 zones of toolhead heating at 1 kW each.

Related search that may be useful or merged/integrated