CEB Press/Research Development

| CEB Press | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

High Level Overview:

CEB Considerations 2015

Design of subsystems:

Mechanical Drawings

- 3D

- File:CEBIV-new.zip Solidworks

- File:CEBIV.step STEP AP203

- File:CEBIV2.step STEP AP214

- File:CEBIV.stl

- File:CEBIV.x t

- File:CEBIV.x b

- File:CEBIV.3dxml

- File:CEBPress.FCStd freecad

- 2D (pdf, png, and sldraw)

Grate (including deflectors, hinges, and supports)

CEB Hopper (including saddle)

CEB Shaker (including shields)

CEB Legs (including holders and feet)

CEB Outer Frame (including drawer rollers and shields)

Research

The first prototype was built in January 2008. The build is archived here

People got interested in our open development model...

- Review of the social enterprise experiment by P2P Foundation

- Review by Samuel Rose of Social Synergy

- P2P Foundation review of the economic model

On the 13th of June 2010, we announced the full release of the complete version. This was an improvement over previous designs, with automatic controls and a faster pressing rate. Several people have bought them since then.

Design Description

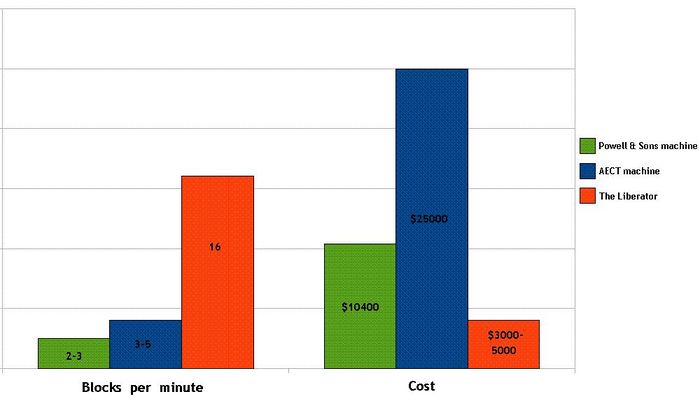

Advantages of The Liberator

- Easy repair. The Liberator was designed to make maintenance as easy and infrequent as possible. The part that is most likely to need replacement is a rubber sheet from McMaster-Carr. The press is designed for disassembly, so if repairs are needed, the cost should be minimal. And unlike commercial machines, you have all the blueprints and sources for parts here, so there should be no difficulty repairing it.

- Requires as little as 1 person to operate. The only control required is turning the machine on, and from that point one simply loads soil and unloads bricks. There is an alternative manual version for $500 less (Is that correct?)

- Modular power source. The Liberator does not have its own power source; it is designed to be attached to an external power source. This is in line with the OSE principle of modularity; different tools can be run from the same power source, allowing the same tool to fulfill many functions flexibly. The power source could be the hydraulics from LifeTrac (our tractor any flexible source of machanical power), Power Cube, or any hydraulic power source with a capacity of 6 gallon per minute (22.71 liters per minute).

- Large hopper. Compared to other CEB presses on the market, The Liberator has a very large hopper. We found with earlier editions that a small hopper requires constant loading and this slows down the production process.

Links to Other CEB Presses

Potential Upgrades

- Eliminate hydraulic shaker use mechanical shaking:

Fact; the soil mix drawer moves several times each cycle.

Use that motion to shake the hopper each cycle. - John S

- Reduce the HP required to power the CEB Press:

A small electric motor or i.c. engine is coupled to hydraulic pump.

Between the motor or engine and the pump locaate a pully or gear to a flywheel.

When the press is not using power, the flywheel is spun up to full rpm storing energy.

When more energy than motor/engine alone is needed the flywheel slows providing this energy

- CEB_Press_Molds

- Adaptation of the CEB Press for oilseed pressing

- CEB 4 design planning

Links